FURTHER TRAINING IN

MACHINE SAFETY

KNOW-HOW AS A FACTOR FOR SUCCESS

Compliance with standards made simple: Be on the safe side!

Machine safety is nothing new: Manufacturers and operators of machines and plants as well as their suppliers have to know and implement a multitude of legal and normative requirements. Ensuring precisely this functional safety for machines requires practical knowledge on the part of all parties involved, from management to developers and designers, and through to maintenance workers and the safety specialists deployed in the company. This sounds like a real challenge, but it can also be easy – with us.

BECOME AN EXPERT IN YOUR COMPANY

THROUGH TARGETED FURTHER TRAINING IN MACHINE SAFETY

INDIVIDUALLY DEVELOPED

FOR EVERY LEVEL OF EXPERIENCE

As one of the leading suppliers of safety technology and electrical connection technology, Wieland offers a comprehensive service and training portfolio.

Our training courses focus on the following and can also be booked as in-house seminars at your company:

- Machine safety

- Liability and law

- Safety software

- Machinery retrofit

The content of the individual workshops is tailored to the different areas of responsibility of the participants and, depending on the depth and breadth of the subject, is aimed at beginners, advanced learners, or experienced experts with at least two years of practical experience.

PRACTICAL TRAINING

FOR EVERYONE IN THE COMPANY

Everyone in the company can benefit from your practical knowledge and will appreciate your new skills, be they decision makers or operational managers, technicians or developers, designers, or maintainers of machines and plants, or safety officers.

Our training courses and seminars in machine safety bring together committed participants from a variety of fields, including:

- Managing Directors

- Operations Managers

- Developers

- Mechanical Engineers

- Machine Setters

- Service Technicians

- Maintenance Personnel

- Safety Officers

YOUR INTRODUCTION TO MACHINE SAFETY:

SEMINARS & COURSES FOR NEWCOMERS, EXPERIENCED USERS & EXPERTS

Experienced specialists from Wieland with proven expertise impart the latest specialist knowledge on laws, directives, and standards in our online and classroom courses throughout Germany. Our seminar offerings are tailored to the different areas of responsibility and prior knowledge of the participants – for newcomers, more experienced users, or experts, for example. The trainers and instructors are happy to address individual and application-related questions or concerns and convey practical know-how in a comprehensible and readily accessible manner. Benefit from more than 30 years of experience in the field of machine safety and take advantage of our wide range of training courses, seminars, and workshops.

Did not find a suitable date? |

TÜV-CERTIFIED COURSES

With us, you will become a certified machine safety expert in just 3-5 days: In cooperation with SGS-TÜV Saar, our experienced trainers will teach you all the legal and normative basics required to be able to evaluate the functional safety of machines and plants as well as to design and calculate safety functions. After successful completion of the course, you will receive an internationally recognized title with which you can clearly prove your qualification. A prerequisite for participation in these courses is at least 2 years of professional experience in the development, maintenance, or design of functional safety systems.

CERTIFIED ELECTRICAL SAFETY EXPERT

The machine safety seminar “CESE – Certified Electrical Safety Engineer” covers the safety aspects of machines and plants with a focus on electrical engineering. Get certified in just 3 days with this seminar focusing on electrics and use this course in machine safety to supplement your practical work experience with the latest expertise.

REFRESHER SEMINAR – CERTIFIED SAFETY EXPERT

Stay up-to-date: The titles Certified Safety Engineer and Certified Electrical Safety Engineer are only awarded for 4 years. To ensure that you always stay up to date with thelatest standards and laws,refresh your certification as a machine safety expert - in a compact one-day seminar including a refresher examination.

BASIC COURSES ON STANDARDS AND LIABILITY ISSUES

The most important basics taught in a practical manner: CE conformity and the corresponding requirements play an important role not only in machine operation, but also in machine sales. In our basic seminars, we convey the principle of functional safety, the standards and laws based on it, and the individual steps to achieving CE conformity in a way that is appropriate for the target group.

MACHINERY DIRECTIVE, CE DECLARATIONS OF CONFORMITY, AND LIABILITY ISSUES

We answer formal questions about machine safety from the perspective of management and purchasing teams in a compact and understandable way in our machine safety training program “Maschinenrichtline, CE-Konformitätserklärungen und Haftungsfragen”.

BASICS OF FUNCTIONAL SAFETY

For safety officers and managers without prior knowledge, we havedeveloped the machine safety training course "Fundamentals of Functional Safety", which provides a basic understanding of functional safety as well as an overview of the most important standards and terms in just one day.

RETROFITTING OLD MACHINERY AND MAJOR CHANGES

What needs to be considered when modifying and retrofitting machines with regard to the CE declaration and how linking machinery affects their CE are topics that are covered in the course “Retrofitting old machinery and major changes”.

SAFETY CONCEPT, VERIFICATION, AND VALIDATION

Calculate hardware, validate software: The software wizard SISTEMA (safety of controls on machines) enables developers and testers of safety-related machine controls to evaluate the machine safety in accordance with EN ISO 13849-1. Likewise, the software tool Softema provides help with validation and ensures a structured work process.

DESIGN OF SAFETY FUNCTIONS AND CALCULATION WITH SISTEMA

In our machine safety training course “Design of safety functions and calculation with SISTEMA”, you will learn in one day how to model and evaluate the safety of your own machine in accordance with EN ISO 13849-1 using SISTEMA.

VALIDATION OF SAFETY USER SOFTWARE IN MECHANICAL ENGINEERING AND PLANT CONSTRUCTION

The machine safety training course “Validation of safety user software in mechanical engineering and plant construction” conveys the work required in software validation in a practice-oriented manner and addresses the typical characteristics of development environments in relation to the requirements of EN ISO 13849-1.

SAFETY IN MACHINE OPERATION

Plant safety and machine safety are crucial for safe, trouble-free operation. For new machines and plants, safety is guaranteed by a CE marking, but after many years of operation or a conversion, the question arises:

How safe are your machines?

RETROFITTING OLD MACHINERY AND MAJOR CHANGES

In the retrofit training covering major changes, impact of interlinked machines, and documentation of retrofitting measures, you will receive the latest information on the CE declaration after retrofitting measures and will learn how to preserve the validity of the old certification so that recertification is not required.

TESTING OF OPTOELECTRONIC PROTECTIVE EQUIPMENT

The legal and normative principles for the design and correct testing of electro-sensitive protective equipment (ESPE) are taught by our experienced trainers in the machine safety training course “Testing of optoelectronic protective equipment”. In this compact machine safety training program, you will not only gain sound theoretical knowledge, but also have the opportunity to practice initial and recurring testing and evaluation of the functional safety of optoelectronic protective equipment.

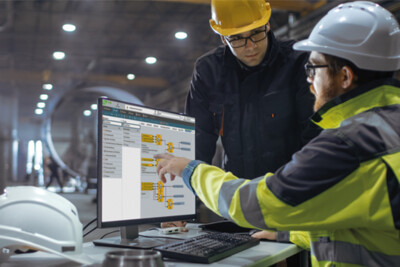

SOFTWARE COURSE ON SAMOS® PLAN 6

Standards-compliant programming of safety functions: In the one-day training courses, you will learn how to efficiently operate and use the samos® PRO safety controller with many practical examples . Designing, programming, verifying and validating safety functions: Do you already know and use all the features of the most compact, modular and programmable safety control for machine and plant engineering?

PROGRAMMING WITH SAMOS® PLAN 6

In a practical hands-on seminar “Programming with samos® PLAN 6”, either in Bamberg or in-house at your company, our experienced experts will introduce you to the software with all its functions and give you valuable tips for working efficiently with the software and the associated safety controller samos® PRO COMPACT.

INHOUSE AND

EXCLUSIVE SEMINARS

Training without the stress of travel:

All our courses on the subject of machine safety take place on varying dates in our modern training rooms in Bamberg. Upon request, our experts can also come to you to conduct the machine safety training at your company. Save on travel time and travel expenses and have your team trained by our experts on your premises.

Exclusive and customized:

Workshops and training courses according to your specifications. Have you not found the right machine safety training program for you in our training package? Would you like a customized workshop with machine safety topics that are relevant to your company? We would be happy to design exclusive workshops and courses to meet your requirements – or to combine topics from various courses to create a customized training course.

Is your desired date still available?

Send us a message without obligation or call us directly on +49 951 9324-0. We will be happy to assist you!

FREE WEBINARS FOR PROFESSIONAL DEVELOPMENT

Do you want to find out about topics relating to functional machine safety in a particularly compact form? You can access our free webinars from the comfort of your own desk or home office. Our experts will spend one hour each time informing you about current developments and product highlights and will be available to answer questions from any participant at any time. The webinars are held online in English and German and provide basic information on the chosen topic.

Here you will find our current webinar dates and topics.

| Date | Duration | Title | Location | Language |

|---|

Did not find a suitable date? |

TRAINING AT ANY TIME:

If there are currently no webinars with topics relevant to you, you may find what you are looking for in our on-demand webinars. These arerecordings of current live webinars that you can use free of charge and at any time.

OUR TRAINERS AND INSTRUCTORS

FOR YOUR TRAINING IN MACHINE SAFETY

Marcus Scholle

Practical expertise: For more than 10 years, Marcus Scholle has been dealing with functional safety in mechanical engineering and plant construction. Based on his experience as a process manager in the design of complex machine assemblies, he is an expert in the integration and programming of safety controllers from different manufacturers as well as in conformity assessment and retrofitting.

Peter Winter

A seasoned expert: This Functional Safety Engineer who specializes in consulting can draw on more than 30 years of experience in electrical plant maintenance. Peter Winter is also the point of contact for all safety applications and, thanks to his many years of professional experience, knows the operator’s point of view particularly well.

Matthias Taub

Matthias Taub works for Wieland Electric as a sector manager for mechanical engineering and, as a certified Safety Engineer, has extensive know-how in the field of machine safety. Thanks to his many years of experience as a manager of a wide variety of projects, he knows exactly what users need and what “best practice” looks like.

Wolfgang Onderka

A technical ace in the field of functional safety: Wolfgang Onderka has been at home in automation technology for more than 15 years and has been advising customers on all issues related to functional safety for machines ever since. His expertise as a consultant and trainer is not only theoretical. Through worldwide service assignments in the field of control technology, he has supervised numerous projects throughout the entire machine life cycle - from planning to commissioning.

LEONARDO SANCHEZ

An expert in the field of international standards and regulations. He knows what conformity with standards looks like in an international context - not only in North and South America, but also in Europe, and provides advice not only to customers operating nationally, but also to companies with a strong export focus. With more than 20 years of experience, he also knows how to implement functional safety in a practical context, bringing together standards compliance with realistic process procedures.

THREE GOOD REASONS

FOR TRAINING WITH WIELAND

TRAINERS WITH

PRACTICAL EXPERIENCE

Our trainers are consultants who guide mechanical engineers on the path to CE conformity every day. What this means for you is up-to-date, practical know-how, processed and conveyed in a manner you can understand.

INFORMATION INSTEAD

OF ADVERTISING

The contents of our seminars and training courses for further education in machine safety are not designed for our products , but convey practice-relevant contents. Acquire a wide range of know-how on different aspects of machine safety - across industries and independent of manufacturers and brands.

DIRECT, FAST CONTACT

Do you still have questions for us? Use our call-back service and arrange to receive a call from our experts – without obligation and without being put on hold.