- CFF - FLUID MODULES

- TRAINING

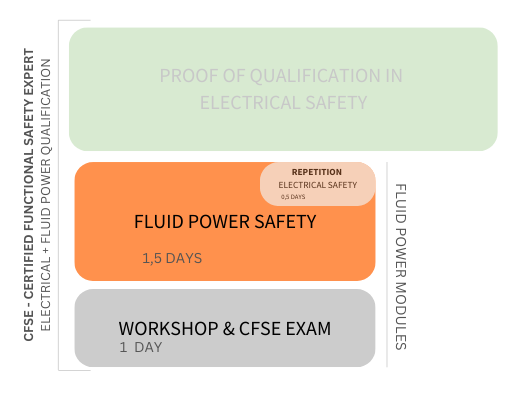

Certified Functional Safety Expert by SGS TÜV Saar –

Advanced course with focus on fluid power safety

Course option for Certified Functional Safety Expert by SGS TÜV Saar with existing electrical qualification.

Do you already have a current qualification in electrical safety and would like to complete the overall qualification as a Certified Functional Safety Expert by SGS TÜV Saar including Fluid Power Safety?

Then attend the advanced course and get to know the Fluid Power Safety procedure. This partial course enables you to attend the fluid technology modules separately, supplement your existing knowledge of electrical safety and take the overall examination covering both subject areas.

DATES

When selecting your preferred date, please pay attention to the location and the language of the lecture. Indicate your preferred date in the registration form.

| Date | Duration | Title | Location | Language | |

|---|---|---|---|---|---|

| 26.02.2025 | 3 days | Certified Functional Safety Expert - Fluid modules - 2.5 days | Mississauga, Canada | EN | |

| 09.04.2025 | 3 days | Certified Functional Safety Expert - Fluid modules - 2.5 days | Bamberg | DE | |

| 30.04.2025 | 3 days | Certified Functional Safety Expert - Fluid modules - 2.5 days | Ferndale - Michigan, USA | EN |

REGISTER

Please note that the training prices may vary depending on the country of the event.

You can find the current prices for each country in the table above.

The customer's registration constitutes a binding application to conclude a corresponding training contract. This application will be accepted or rejected by a confirmation from us at least one week before the start of the training course (for more information, please look at our terms and conditions).

Within this online form, you apply for the advanced training (2,5 days) , covering the fluid power portion of the class. If you would like to participate in both the electrical and the fluid power content of the class, see the dates for the 5 day course.

You have questions regarding our course? Write us an email

- Courses in Canada: marketing.canada@wieland-electric.com

- Courses in the US: marketing.canada@wieland-electric.com

- Courses in the UK: sales.uk@wieland-electric.com

- Courses in Germany: training@wieland-electric.com

*Refresher seminars for graduates of previous courses can be found here

BOOK THIS SEMINAR AS AN

IN-HOUSE TRAINING

As an alternative to our regular training sessions, we also offer customised in-house training courses. Our experts will be happy to come directly to your company. Find out more about our in-house training courses and contact us to receive a customised offer.