CE Marking

for Machines

Securely SUPPORTED – Professional Guidance

for CE Marking

Machines with CE marking comply with EU directive requirements and ensure safe operation. It is the basic prerequisite for the sale and use of machines in Europe. To ensure that the self-declaration is compliant with standards, a structured conformity process is essential.

We help you understand and confidently implement this process – from risk assessment through verification and validation to complete documentation. With valuable expertise and hands-on support, we actively accompany you throughout your project.

WHY SUPPORT IN THE CE PROCESS MAKES THE DIFFERENCE:

FROM CHALLENGES TO OPPORTUNITIES WITH WIELAND

⚙️ THE CHALLENGE

Achieving CE compliance for a new machine – frequently asked questions:

- Complying with standards and directives: Which regulations apply to your machine?

- Optimizing the safety concept: How can it be designed to be both safe and productive?

- Documenting measures correctly: What requirements must be met?

- Clarifying responsibilities: Who is qualified to carry out these measures?

🚀 THE OPPORTUNITY

Streamline your processes and demonstrate professionalism:

- Clearly define processes to ensure smooth operations.

- Achieve legal certainty by meeting all applicable standards.

- Prove quality and reliability to strengthen customer trust.

- Build internal knowledge sustainably so your team can act independently in the long term.

🔧 THE SOLUTION

We are your sparring partner in all aspects of functional safety:

- Consulting on compliance and legal certainty to ensure you’re well-positioned.

- Evaluating existing documentation and systems to close safety gaps.

- Developing professional risk assessments, verifications, and validations – tailored to your machines.

- Reviewing or creating complete documentation to ensure CE compliance.

- Providing training and workshops so your team is fully prepared.

EMPOWER YOUR FUNCTIONAL SAFETY EXPERTISE

WITH INSIGHTS FROM WIELAND!

Expert Knowledge from Standard Committees

Our instructors combine their active participation in standard committees with practical implementation experience, ensuring you benefit from the latest standards and real-world expertise.

Shape Our Services with Your Real-World Insights

At Wieland, we tailor our services to your needs. Share your challenges and questions in advance of sessions like the Machinery Regulation TechTalk for targeted, customer-specific insights.

Global Multilingual Support

We provide services, consultations, and training in multiple languages, including English, German, Chinese, Spanish, and Polish (on request). As a global company, we ensure effective communication for your international needs.

Customized Solutions for Your Needs

We deliver tailored training, services, and consultations. On request, we arrange follow-up sessions to provide targeted support and ensure your long-term success.

NAVIGATE THE CE CONFORMITY PROCESS WITH CONFIDENCE

– BACKED BY OUR EXPERTISE

We guide you through every phase of the CE process – from initial concept to final inspection – with precision and transparency. Our in-depth expertise ensures compliance while helping you save time and resources. Discover how the CE process, structured into 9 clearly defined steps, ensures that your machines meet all safety and regulatory requirements efficiently. With our tailored guidance, your path to CE conformity is smooth, reliable, and effective.

01 Research

The first step toward CE marking: Identifying all relevant standards and directives for your machine type.

02 Risk Assessment

Systematically analyzing hazards and assessing risks to establish the foundation for the safety concept.

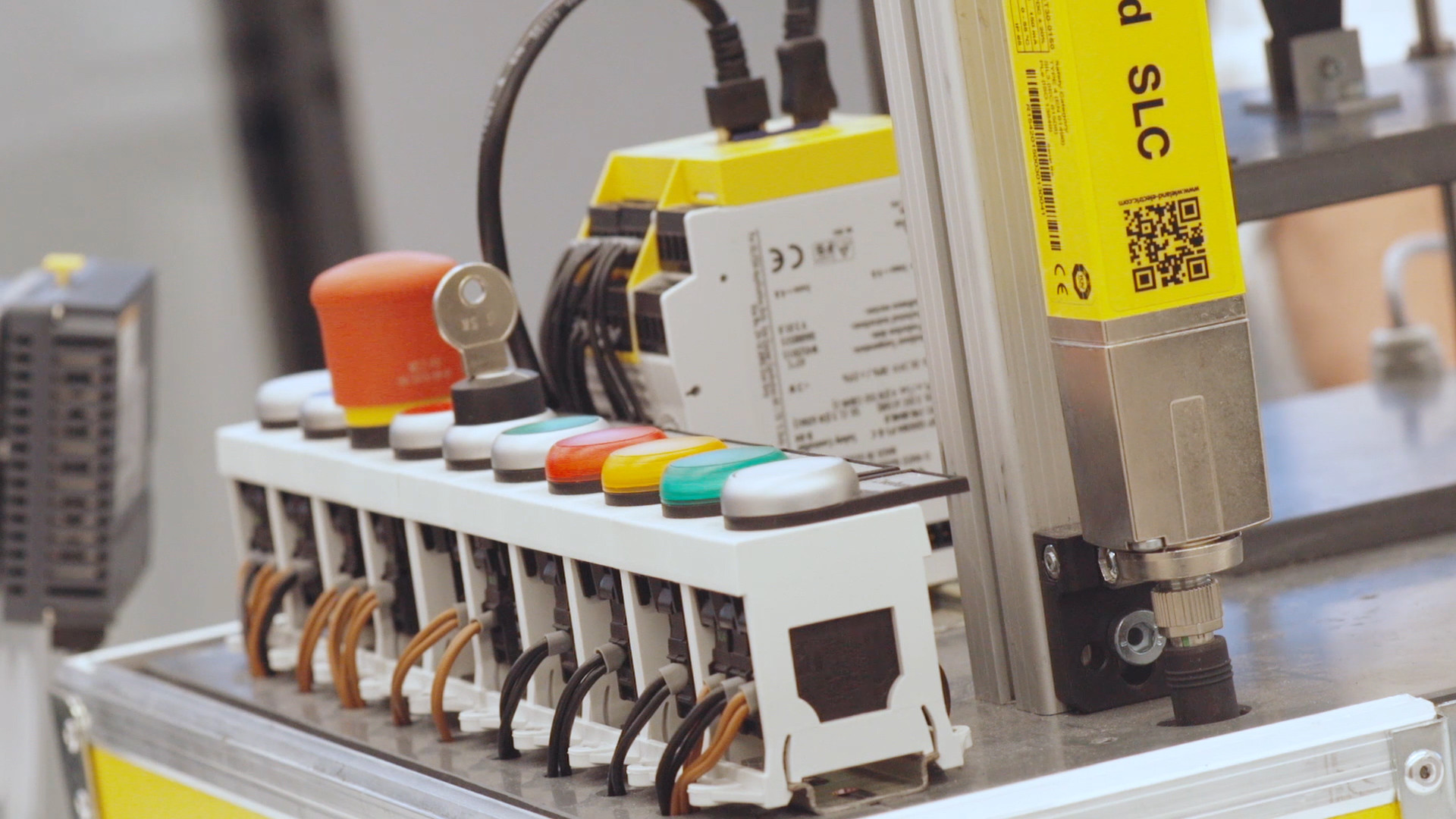

04 Safety Engineering

Implementing technical safety measures and developing safety-related software based on the concept.

03 Safety Concept

Developing a safety concept in accordance with standards, defining protective measures and integrating them to support productivity.

05 Verification

Systematically verifying whether the protective measures meet all Performance Level requirements.

07 Documentation

Compiling all evidence and reports to document CE conformity and provide legal assurance.

09 Inspection

Performing regular inspections and overrun distance measurements to ensure long-term safety and compliance with standards.

06 Validation

Conducting practical checks of the protective measures directly on the machine to ensure functionality.

08 Evaluation & Final Report

Preparing a comprehensive final report that evaluates results and identifies potential for improvement.

CONSULTING AND SERVICES FOR MANUFACTURERS AND OPERATORS

Whether you are developing, commissioning, or operating machines – your responsibility in the CE process is crucial for ensuring safety and compliance. As a manufacturer or operator, you face different challenges that we solve together with you.

MANUFACTURER / INTEGRATOR

As a manufacturer or integrator, you are responsible for the safe design of your machines. This includes:

- Compliance with legal requirements: such as the Machinery Directive 2006/42/EC.

- Efficient implementation of all requirements: from risk assessment to the CE declaration of conformity.

Our support: We provide comprehensive consulting for every step to help you bring your machines to market in a compliant and safe manner.

OPERATOR

As an operator, you are responsible for ensuring that your machines are operated safely and in compliance with standards. Typical tasks include:

- Regular safety assessments: to verify protective measures.

- Ensuring compliance with standards: so your machines meet all applicable requirements.

Our support: We inspect safety systems, assist with hazard assessments, and support you in retrofit projects.

CONSULTING SERVICES for the CE Process

Access our expertiseYOUR GLOBALLY TRUSTED PARTNER

Wieland supports you with a global network of experts and in-depth knowledge. We help you understand and implement specific requirements – through comprehensive consulting, specialized services, or hands-on training.

Get support in developing country-specific requirements – and bring your machines to all markets in a legally compliant and efficient manner.

DECLARATION OF CONFORMITY ACCORDING TO EU DIRECTIVES

If you want to offer or export machines or systems in the European Economic Area (EEA), you must comply with clear directives and standards. A solid understanding of legal requirements and a smooth CE conformity process are essential.

NATIONAL & INTERNATIONAL APPROVALS

Do you want to market machines or systems outside the European Economic Area (EEA) as well? Then you must comply with the national approval requirements and standards of each respective country – from UL and CSA in North America to CCC in China and other local regulations worldwide.

CE (Conformité Européenne)

Indicates that a product complies with applicable EU directives and regulations.

UKCA (UK Conformity Assessed)

Replaces the CE marking for the UK market and confirms compliance with British standards.

EAC (Eurasian Conformity Mark)

Marking for compliance with technical regulations in the Eurasian Economic Union (EAEU), including Russia, Belarus, and Kazakhstan.

CCC (China Compulsory Certificate)

Mandatory certification for certain products sold or used in China.

RCM (Regulatory Compliance Mark – Australien & Neuseeland)

Indicates compliance with electromagnetic compatibility and safety requirements in Australia and New Zealand.

NR-12

The Brazilian NR-12 regulation sets strict requirements for machine safety in terms of operation and legal compliance.

cULus (Underwriters Laboratories US & Canada)

Confirms that a product meets the safety requirements for the U.S. and Canadian markets.

CSA (Canadian Standards Association)

Certifies compliance with Canadian safety standards for electrical and industrial products.

FAQ

Machines with a CE marking comply with the requirements of the European Union directives. This marking is a prerequisite for the sale and operation of machines, which is why this regulation applies in all EU countries.

According to Article 114 of the EU treaties, the manufacturers of the products mentioned in the following directives are affected:

- Machinery Directive 2006/42/EC

- Low Voltage Directive 2014/35/EC

- ATEX Directive 2014/34/EC

- EMC Directive 2014/30/EC

- Pressure Equipment Directive 97/23/EC

- Simple Pressure Vessels Directive 2009/105/EC

- Product Safety Directive 2001/95/EC

... and, according to Article 153, the operators with regard to the aspects of the

- Occupational Health and Safety Framework Directive 89/391/EEC

- Work Equipment Directive 89/655/EEC

- ATEX Operating Directive 1999/92/EC

In addition to protection targets for machinery, the EU Machinery Directive also defines areas of application and assessment procedures. Harmonized standards help with implementation.

Suitable standards exist, among other things, for

- the risk assessment procedure (assessment, mitigation, evaluation),

- the evaluation of safety functions and

- the implementation of safety requirements.

The prerequisite for CE marking is a manufacturer's declaration of conformity. This officially confirms that the product (in our case the machine) complies with the requirements of all EU directives applicable to the product. The declaration of conformity must be documented in detail by the manufacturer. In the case of the Machinery Directive, this includes the risk assessment, the technical documentation and the operating instructions for the machine.

In Germany, the Product Safety Act (ProdSG) applies. According to this law, the "person placing the product on the market" is liable. According to § 2 ProdSG, persons or companies who make a product or machine available on the market for the first time are those who place it on the market. Operators can also become manufacturers if they substantially modify machines, assemble systems or complete machines. Anyone who imports machines from outside the EU is also responsible for conformity with the directive and is liable accordingly.

Basically, the EU Directive 2006/42/EC applies to

- Machinery

- Replaceable equipment

- Safety components

- Load handling attachments

- Chains, ropes and belts

- Removable cardan shafts

- Incomplete machines