HTL-INCREMENTAL ENCODER SERIES SENC

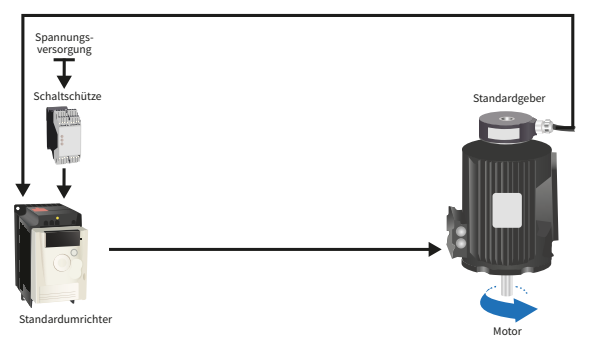

Incremental encoders are the simplest and most commonly used type of encoder. They are suitable for monitoring speed, position, and direction of rotation. They can be connected to common PLC and PC control systems and are a very robust fundamental element of industrial control systems.

SERIES SENC

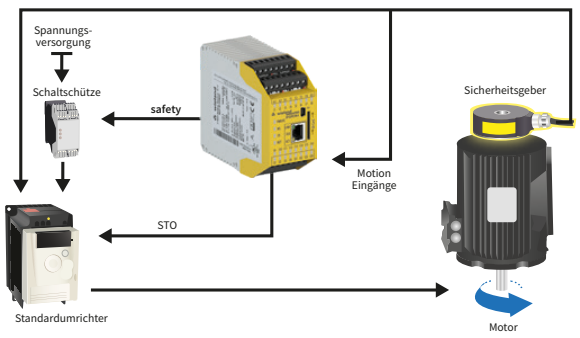

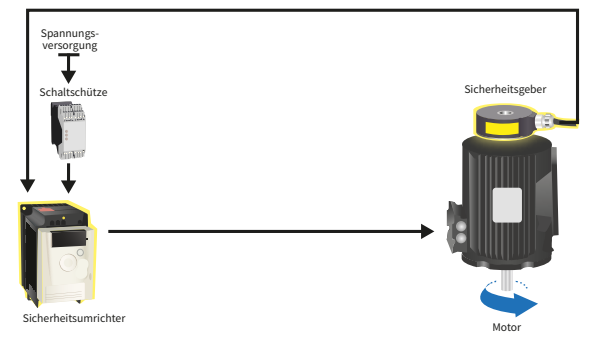

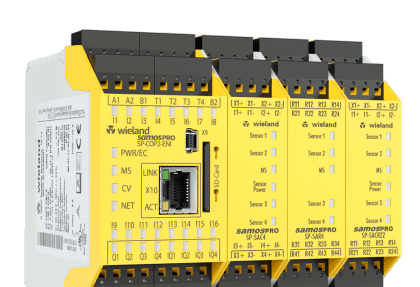

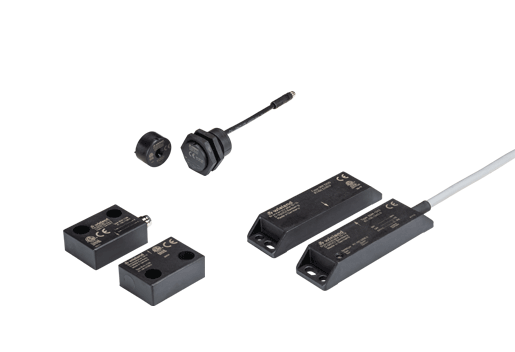

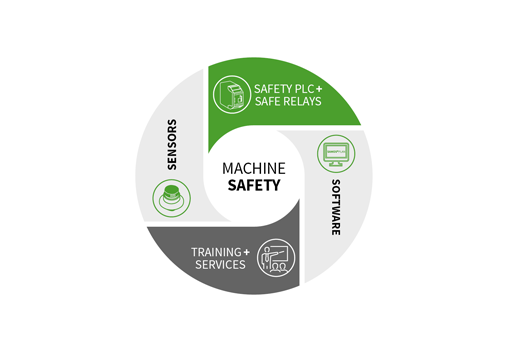

Automation systems often require a high level of risk minimization. In such systems, equipment with functional safety can be part of the solution. Wieland offers encoders with functional safety for almost any application or electrical interface requirement. These encoders are rated SIL3 (PLe) and enable safe operation in setup, production, and maintenance modes, significantly reducing operational risks.

VARIANTS

ACCESSORIES FOR SENC ENCODERS

Torque supports provide a high degree of rotational stability to prevent the encoder from rotating with the shaft. Flange adapters are used to flange-mount the encoder to a motor.

With reducer sleeves, you can reduce the diameter of a hollow shaft encoder. PUR encoder cables with M23 connectors (encoder-side) and open wires (control-side) offer high flexibility, robustness, and resistance.

TECHNICAL DATA

Detection of positional or angular changes via square-wave pulses using photoelectric scanning.

Detection of positional or angular changes through square-wave pulses using photoelectric scanning.

24 V DC

24 V DC

11 – 30 V DC

11 – 30 V DC

100 mA no-load current

100 mA no-load current

Digital HTL Signals (11-30 V DC)

Digital HTL Signals (11-30 V DC)

A, A/, B, B/ for safe incremental pulses

A, A/, B, B/ for safe incremental pulses

A: gray, A/: pink, B: brown, B/: green, 0: red, 0/: black, +V: blue and green/brown, 0V: white and white/green

A: gray, A/: pink, B: brown, B/: green, 0: red, 0/: black, +V: blue and green/brown, 0V: white and white/green

360 ppm and 1024 ppm

360 ppm and 1024 ppm

40 mA

40 mA

58 mm

58 mm

Solid shaft

Hollow shaft

10mm

14mm

Powder-coated zinc die-cast

Powder-coated zinc die-cast

Aluminum

Aluminum

AISI 303 stainless steel

AISI 303 stainless steel

Series 6800 – sealed

Series 6803 – sealed

Axial: 40 N, Radial: 80 N

Axial: 20 N, Radial: 40 N

Moment of inertia of the shaft

Less than 2800 g.mm²

Less than 2800 g.mm²

5 / 35 mN.m

10 / 85 mN.m

9,000 RPM

9,000 RPM

Maximum continuous speed

6,000 RPM

4,000 RPM

Greater than 29.7 x 109 revolutions / 82,365 hours

Greater than 24 x 109 revolutions / 100,000 hours

0.300 kg

0.280 kg

IP65

IP65

-25°C to +85°C / -20°C to +85°C

-25°C to +85°C / -20°C to +85°C

EN/ IEC 61508, IEC 13849-1, IEC 61800-5-2, IEC 62061

EN/ IEC 61508, IEC 13849-1, IEC 61800-5-2, IEC 62061

CE, TüV, cULus Listed

CE, TüV, cULus Listed