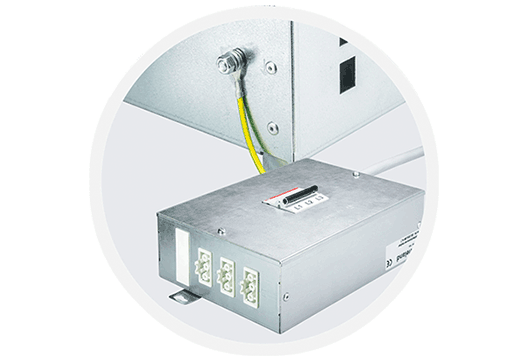

DISTRIBUTION BOX RAU

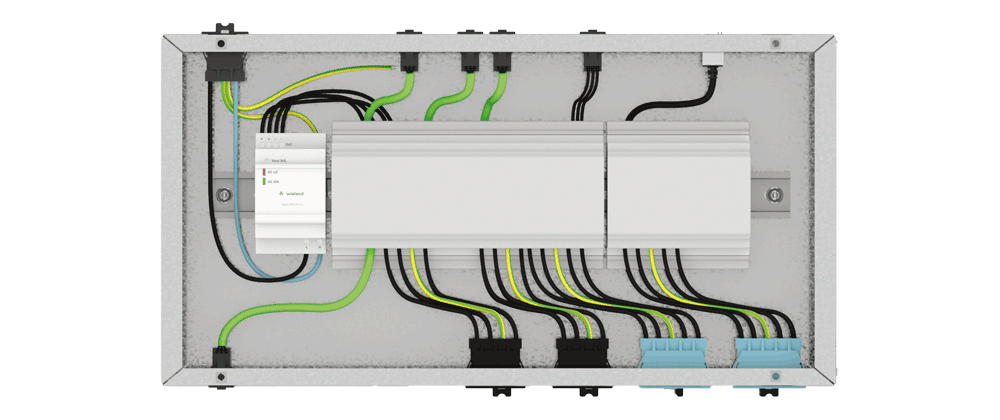

With our smart distribution boxes we offer you the necessary framework for your energy-efficient room automation

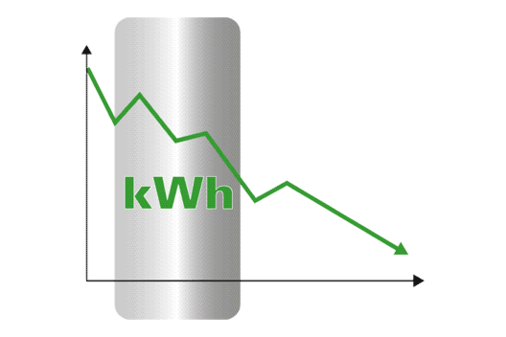

STUDY OF THE UNIVERSITY OF BIBERACH ON THE SUBJECT OF ENERGY SAVING

A scientific study in three rooms with different automation levels was conducted at Biberach University of Applied Sciences during the lecture period. Considerable savings potential was identified within the process. More than 30% is possible for electrical energy consumption and even more than 50% for heating energy consumption! And all this in the existing structure without any structural changes.

The study "Energy Efficiency through Building Automation" was conducted over a period of three years by Professor Dr.-Ing. Martin Becker and his team.

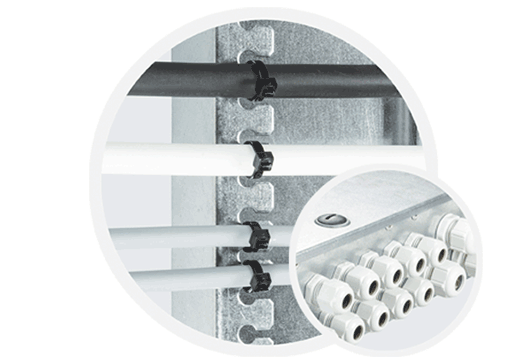

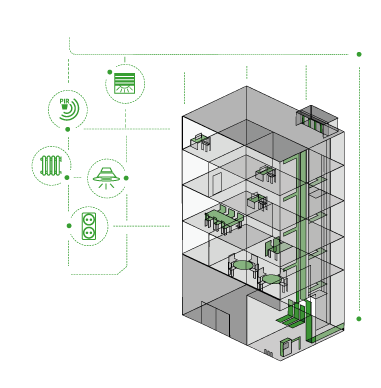

ROOM AUTOMATION INSTALLED DECENTRALLY

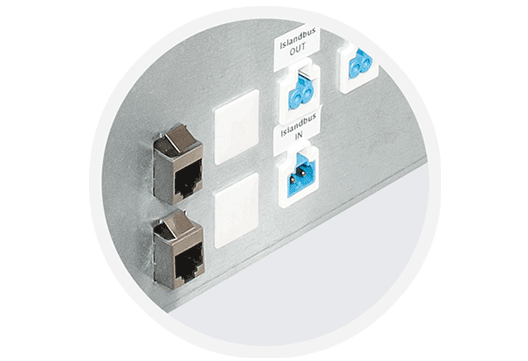

The areas of lighting, shading and room temperature are responsible for an optimal working atmosphere. Intelligent room automation devices are essential to ensure that they perform their task ideally. For fast, flexible and safe installation, we integrate the devices into the pluggable, decentralized electrical installation with our distribution boxes.

AREAS OF APPLICATION OF THE DISTRIBUTION BOXES RAU

INTELLIGENT ROOM AUTOMATION DEVICES

PROCEDURE FOR YOU AS A PLANNER

What does a building installation with our products mean for you?

First of all, a few basic questions should be clarified.

- What functions are to be integrated?

- What electronics will be used?

- Which room units will be controlled?

- What construction space is available or will be needed?

- Will the plant installation be pluggable?

Contact us and arrange an appointment, during which the necessary details will be clarified. The aim of the appointment is the specification of the distribution box, the definition of the tender text and a cost estimate.

- Specification of electronics and internals

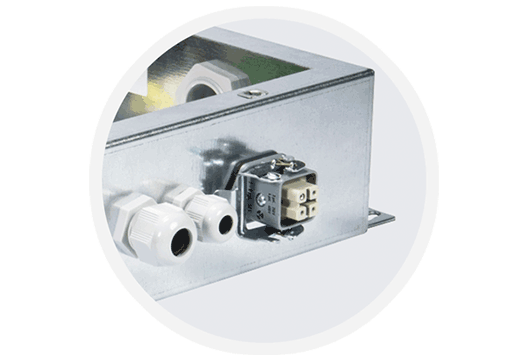

- Determination of the connection type

- Planning the distributor size and material

- Optimization of distribution variants and quantity structures

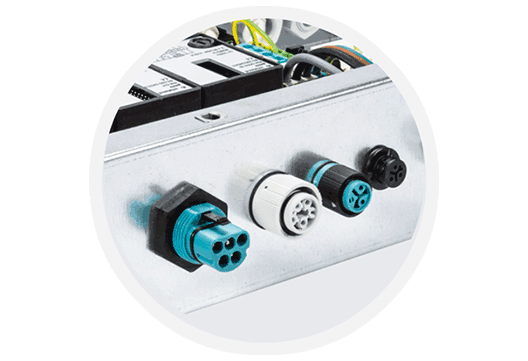

- Determination of accessories such as connectors or assembled cables

They write out the distributors and accessories.

- You receive a cost estimate from us

- We draw up the tender texts together (neutrally as well)

- We handle the queries from installers

The executing company orders the required components.

- Appointment with your Wieland project manager

- Creation of assembly, wiring and connection diagrams (based on AutoCAD, EPLAN)

- Final approval of the distributors by signature of the executing company

- Production and routine testing of the distribution boxes in accordance with the applicable standards and guidelines

- Handover of documents and plans to the contractor

PROCESS FOR YOU AS THE EXECUTING

What changes in the installation and the process?

You produce the cost calculation.

- Request for a quotation from Wieland based on the invitation to tender

- Possibly more detailed specifications

- Preparation of a net offer, as the distribution boxes are individual customer solutions

After the contract has been awarded, you order the distributors.

- Appointment with your Wieland project manager

- Determination of structure and wiring in coordination

- Optimizations based on the real conditions

- Discussion of delivery and logistics

- Drawings are produced by Wieland Electric

- Release for production by customer

- Possibly sampling

The manifolds are manufactured at Wieland according to the agreements.

- Machining and, if necessary, coating of the sheet/plastic material

- Installation and wiring of electronics or further devices with labeling of the distributors

- Unit testing of the manifolds

The distributors are delivered to the desired address as agreed.

- We deliver the manifolds commissioned, together with other components

- Delivery is made on time by forwarding agent to the desired address