DISTRIBUTION BOX MSR

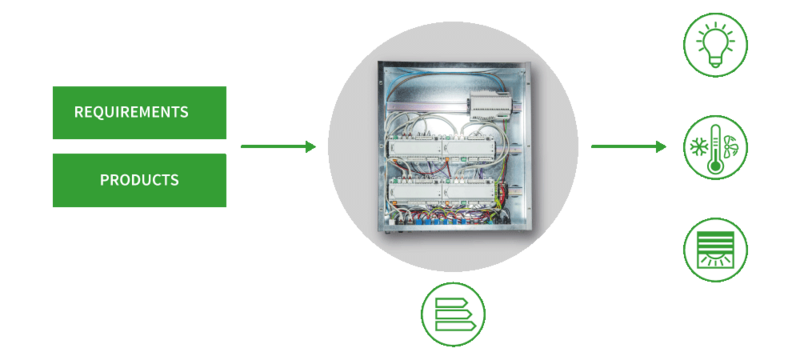

The simple way to install building automation and distribution boxes decentralized and pluggable.

DISTRIBUTION BOX MSR FOR THE BUILDING AUTOMATION

As part of the energy transition and as a way to achieve the associated energy savings, buildings need to become more and more energy-efficient and sustainable. Therefore, legislators and developers are rightly demanding that planners and operators of new buildings and retrofit measures significantly reduce the energy requirements of buildings. The main focus is on sustainability and reducing CO2. The transition to smart buildings requires flexible systems and products with the ability to communicate. This is where a decentralized, electrical installation. Our system distribution boxes can accommodate all the components of building automation and offer pluggable interfaces to the field level for fast and error-free installation. We work closely with the building automation (BA) contractors involved in a construction project.

We can create a system distribution box for your smart building that suits your individual requirements.

THE RIGHT DISTRIBUTOR FOR YOUR APPLICATION

Our MSR distribution boxes are individually tailored to your project.

After determining the spatial axes and functions, we manufacture the system distribution box with your electronics and the necessary interfaces. If you wish, we can pre-assemble the required sensors and consumers with our gesis® installation connector system.

This provides a plug&play solution for a decentralized and pluggable electrical installation all the way to the field level. It also comes with the added benefits of increasing energy efficiency and saving materials and resources.

APPLICATIONS OF THE MSR DISTRIBUTION BOXES

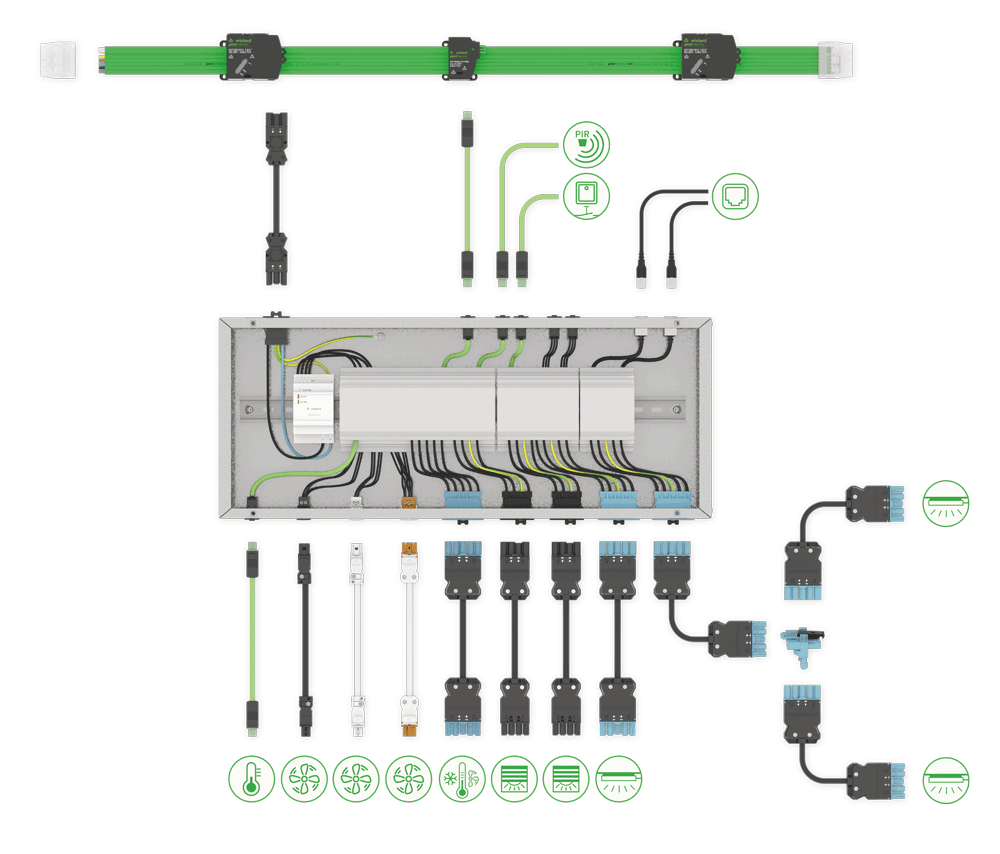

DISCOVER THE INDIVIDUAL SYSTEM COMPONENTS

GESIS® NRG

energy flat cable adapter

GESIS® NRG

bus signal flat cable adapter

GESIS® CLASSIC

power supply input

GESIS® NV

interface for bus signals, e.g. KNX

INTERFACES

to other bus systems, e.g. RS485 / RS 232

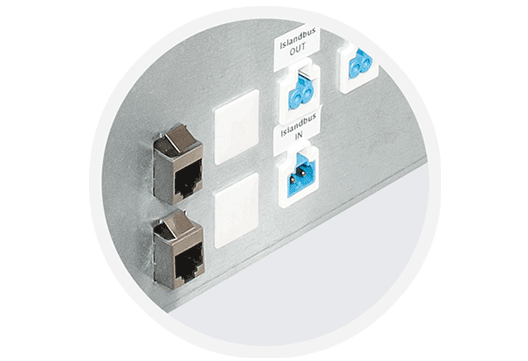

NETWORK CONNECTION RJ45

WIPOS

switched-mode power supply

YOUR ELECTRONICS

automation controllers, I/O modules, etc...

INTERFACES

to the field level

GESIS® CLASSIC

cable assembly

GESIS® MINI

cable assembly

GESIS® NV

cable assembly

GESIS® NRG

backbone for energy and bus signal, e.g. KNX

DISTRIBUTION BOXES - THE BENEFITS FOR YOU

future-proof installations

-

streamlined structures

due to three-phase current up to just before the consumer

we integrate your components of choice

SPACE FOR YOUR ELECTRONICS

We install your components of choice inside the distribution boxes!

- Supplied BA components

- Wieland power supply units and overvoltage protection

- Terminal blocks for wiring the components

- RCB / MCB

- and much more

SUPPORT FOR THE BUS SYSTEMS COMMONLY USED IN BUILDINGS THROUGH PLUGGABLE CONNECTION OPTIONS

BACnet

BACnet (Building Automation and Control Networks) is a network protocol for building automation. This protocol, standardized according to ISO 16484-5, simplifies communication between devices from different manufacturers, from the fieldbus level to the management level.

KNX

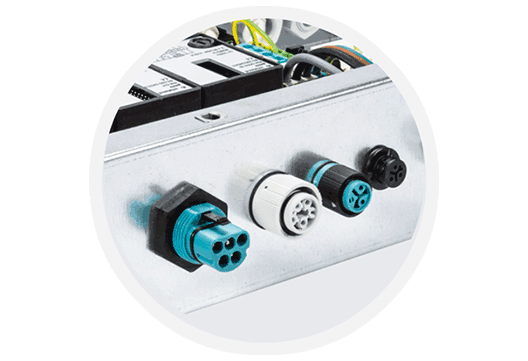

KNX is a uniform and manufacturer-independent communication protocol for the intelligent networking of various building automation functions, which is standardized according to EN 50090 and ISO/IEC 14543. Usually, two-wire bus cabling is used in the building, which is pluggably wired with the gesis® NV plug-in system (type BST14, green) from Wieland.

DALI

DALI is a sub-bus system, according to IEC 62386, for lighting technology that enables 5-pole cabling with mains and signal.

This is installed, for example, with the Wieland gesis® CLASSIC installation connector system (type GST18i5, pastel blue).

SMI

SMI is a sub-bus system for shading technology, which enables 5-pole wiring with mains and signal. This is installed, for example, with the Wieland RST® MINI installation plug-in system (type RST16i5, turquoise blue).

Ethernet or other bus systems

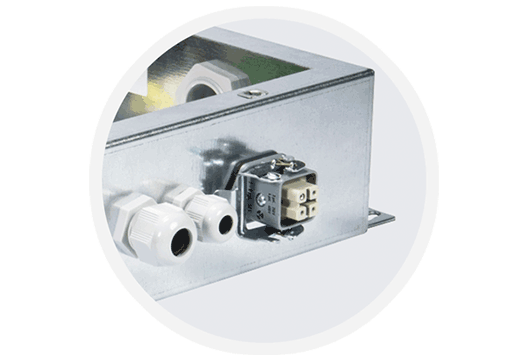

Other bus systems are common in buildings and can also be integrated pluggably.

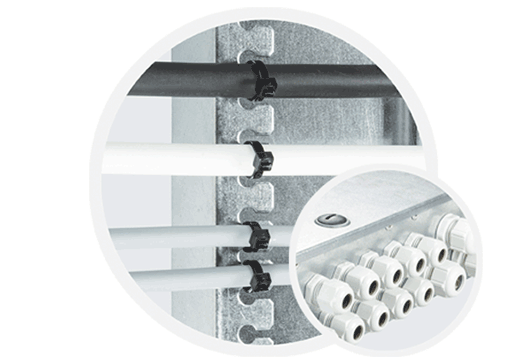

When it comes to planning electrical connections to the outside world, we will provide you with expert advice so that we can come up with the best possible solutions together. These range from 100% pluggability to a simple strain relief, from a sensor cable to high cross sections, from data to power connections.

OUR SMART SERVICES + SERVICES FOR YOUR SUCCESS

We will support you throughout your project, from planning to completion.

LABELING + IDENTIFICATION

Labeling is essential for installation, commissioning, and operation of the equipment. Together with you, we will develop an informative labeling concept for your distributors.

DOCUMENTATION FOR YOU

- Plans

We will supply you with assembly diagrams, wiring diagrams, and parts lists, all in PDF format. By arrangement, we can also deliver the plans on paper and/or in various digital formats as well as, of course, test reports.

- Data sheets and certificates

By arrangement, we can supply you with the corresponding data sheets and CE declarations of conformity for all Wieland components.

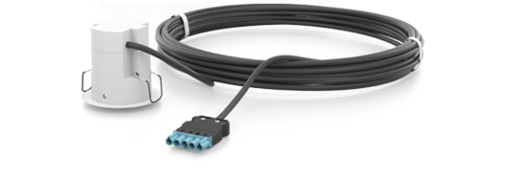

Pre-assembly of third-party devices

We are happy to pre-assemble the necessary peripherals to make sure that the installation is pluggable all the way to the field level.

- Provision of peripherals

- Cable connection at Wieland Electric

- Type and length of the cable and connectors by agreement

DELIVERY OF THE DISTRIBUTORS

We will deliver your distributor, as agreed, at the right time, and to the right place.

We are happy to pick the distributors per area unit with the required accessories.

TESTS CUSTOMIZED AND GENERAL

Quality goes without saying for us, and we monitor this constantly through various tests. Our distributors correspond to the standards and regulations that are fundamental to the intended use. Wiring tests, for example, are performed in principle for every single piece. Custom tests, such as function tests, are agreed separately.

Checking the plans

Before the distributors are made, the plans are presented to our customers for confirmation.

FAQ

- Simple and future-proof structures

- Flexible expansion possible at any time

- Easily scalable systems can be created with small, decentralized system distribution boxes, unlike with large, centralized floor distributors

- Small utility rooms since the automation electronics do not have to be accommodated in the main distribution units. Only the main fuses and the bus system devices remain in the distribution unit

- More net floor area

- Increased energy efficiency – due to three-phase current up to just before the consumer

- Room automation devices are installed close to the load

- Fuse elements (RCB, MCB) on site

| Cable length | 100 |

|---|---|

| Fire load | 100 |

| Technical room | 100 |

| Cable length | 30 |

|---|---|

| Fire load | 40 |

| Technical room | 40 |

From conception to tendering, contract placement, and execution, we will design the process with you.

Contact your responsible sales representative.

From tendering to final design and manufacture at Wieland, through to delivery, we will accompany you every step of the way.

Contact your responsible sales representative.

- We will install the components you have requested or supplied

- Wieland power supply units and overvoltage protection

- Terminal blocks for wiring

- RCB/MCB

- and much more

After clarifying all the technical details with us, you will receive a quotation. If an order is placed, we will check the drawings with you then manufacture the system distribution boxes according to them. You will provide us with your electronics components, and we will integrate these into the system distribution boxes. After final unit testing, we will deliver the distributors to the right place or the agreed address at the right time.

The system distribution boxes undergo a type test, which includes EMC, temperature, IP, IK, and corrosion testing. A unit test is also carried out, involving a visual inspection, a short-circuit and reverse-polarity test, and a continuity test.

A functional test can also be performed at the customer’s request.

For a quick, safe, and error-free installation, we recommend you use the reliable gesis® System from Wieland. If higher IP protection ratings or higher pole counts are required, the RST® and revos systems from Wieland would be suitable. Our system distribution boxes can also be optionally equipped with conventional entries and with couplings for data technology.

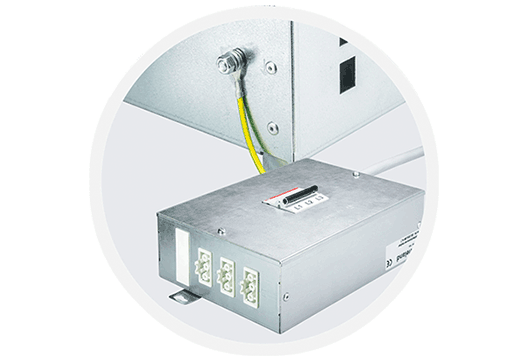

The system distribution box comes as standard with an earthing connection bolt with a standard setup for ring cable lugs.