GESIS® RAN - distribution boxes

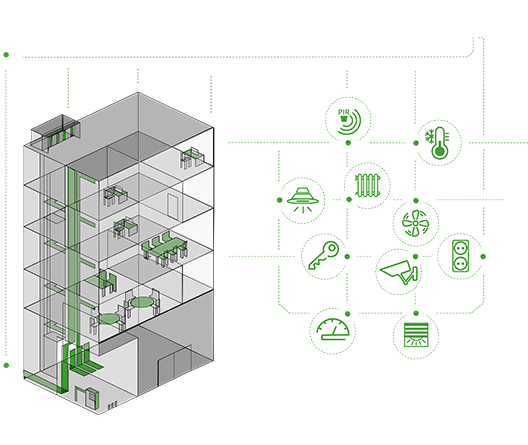

SMART DISTRIBUTION BOXES FOR FLEXIBLE BUILDINGS.

Wieland is your experienced and reliable partner for efficient, pluggable and decentralized electrical installation. Among our distribution boxes you will find the smart and practical solution for your project or business. From power and signal distribution to I&C applications and complete room solutions - we have just what you need.

Our solutions enable short planning and realization times and allow optimized construction processes through prefabrication and configuration. During the planning phase, we naturally respond to your individual project-specific wishes.

AREAS OF APPLICATION FOR OUR DISTRIBUTION BOXES

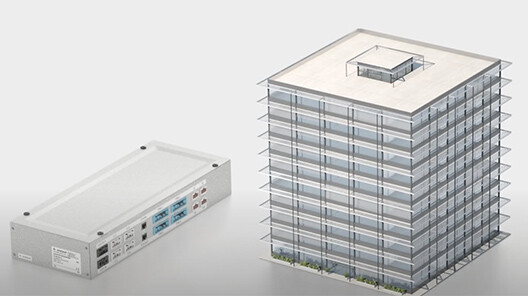

In order to achieve climate targets while saving resources and costs, the energy efficiency of buildings is playing an increasingly important role in new construction and renovation. In addition, the transformation to smart buildings requires flexible, communication-enabled systems and products. Here, decentralized electrical installation has proven its worth: Our distribution boxes offer the necessary installation space for pluggable installation - for the most diverse applications in the most diverse areas of use:

- Office building

- Administration building

- Retail - Shop

- Airports

- Schools / Educational institutions

- Hotels

Our distribution box can be used wherever high demands and harsh environments meet - so even moisture is no problem for our technology.

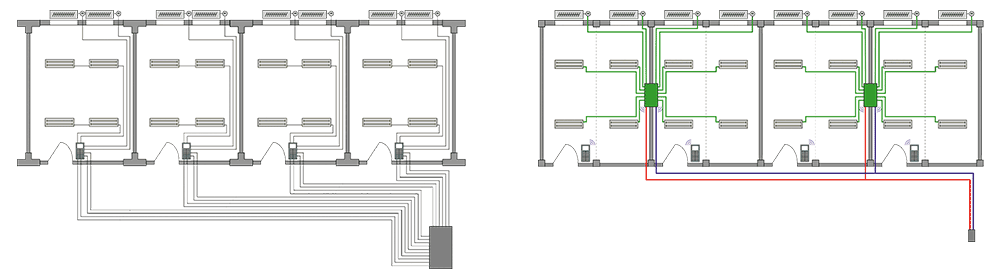

WHAT DISTINGUISHES CENTRALIZED DISTRIBUTION FROM DECENTRALIZED DISTRIBUTION?

CENTRAL DISTRIBUTION - THE ELABORATE PRACTICE | DECENTRALIZED DISTRIBUTION - THE SMART INSTALLATION | |

ENGINEERING ROOM | 100% | approx. 50%* |

LINE LENGTHS | 100% | 30%* |

TRACE WIDTH | 100% | 60%* |

* Values from many years of experience

| Time | 100 |

|---|---|

| Time + Material | 100 |

| Fire load | 100 |

| Time | 54 |

|---|---|

| Time + Material | 68 |

| Fire load | 33 |

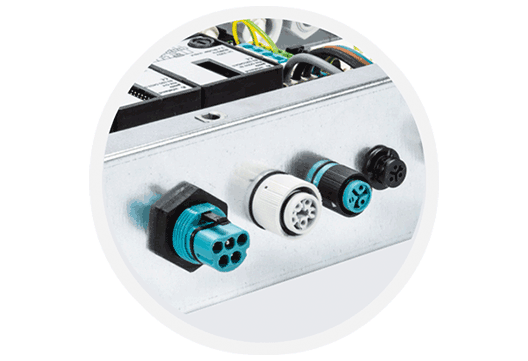

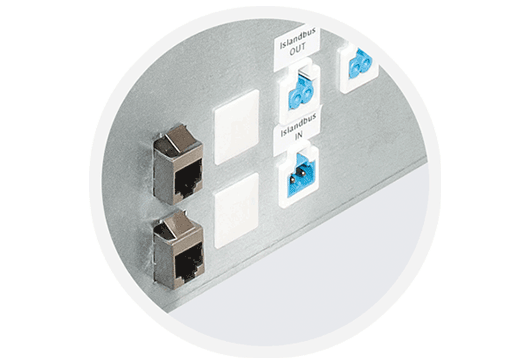

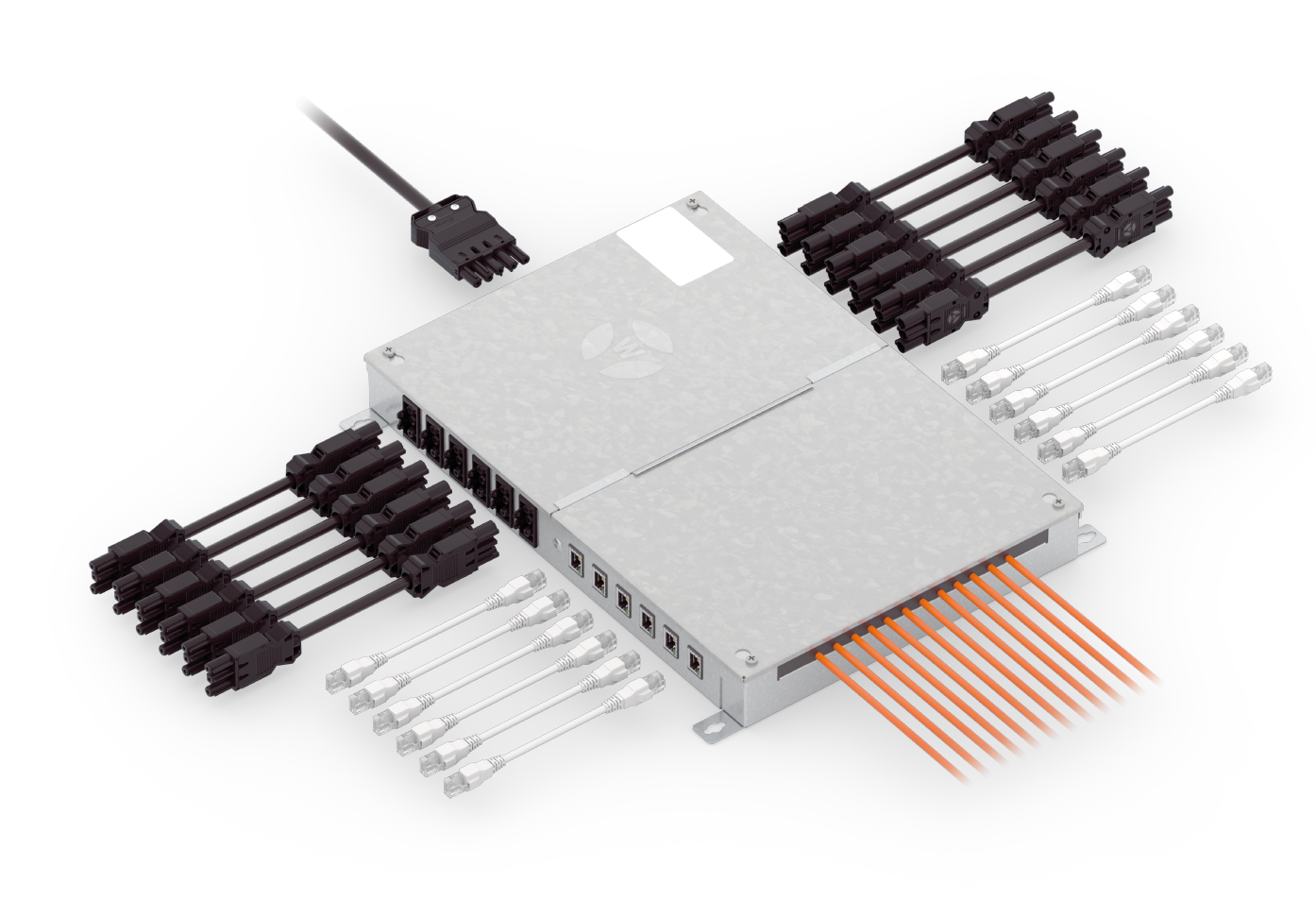

The Wieland distribution boxes, ic compliance to IEC 61439, together with our installation connector systems, in compliance to IEC 61535, as well as its system components form the nervous system of a building for decentralized electrical installation. From decentralized energy, signal and data distribution to distribution boxes for smart buildings, we offer the right solution.

YOUR ADVANTAGES AT A GLANCE

Reliably calculable

Clear structures

Installation of your desired components

WHAT OUR DISTRIBUTION BOXES OFFER

APPLICATIONS DECENTRALIZED INSTALLATION

- Workplace supply

- Energy and data distribution

- Lighting and blinds controls

- Building automation

- Room automation

- and many more

PLANNING

- Small units that can be planned effectively

- Reduction to a few different types per construction

- Individual design

- No need for terminal diagrams of individual wires

- Promotion of a clear management structure

- Reduction of total line lengths

- Support from Wieland

INTERFACES BETWEEN THE EXECUTING COMPANIES

- Simple separation of cabling, assembly and commissioning due to pluggability

- Clear visibility of responsibility boundaries

- Possibility of good company coordination

- Simple design of the construction process - from cabling to commissioning

- Simple analysis possible in case of error

SAFE INSTALLATION

- High degree of industrial prefabrication

- Pre-integration and clear interfaces

- Hardly any documentation work

- Short assembly time

- No installation errors, thanks to the coding of the plug-in system

OPERATION

- Changes easily integrated

- Support for fault localization through pluggability

- Troubleshooting through rapid replacement of the functional units

- Easy attachment of extensions with good pre-planning

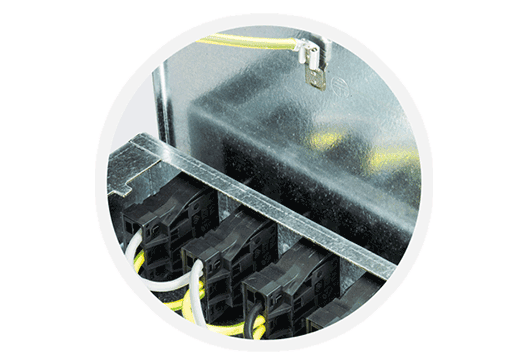

CONFECTION FOR THE FIXTURES

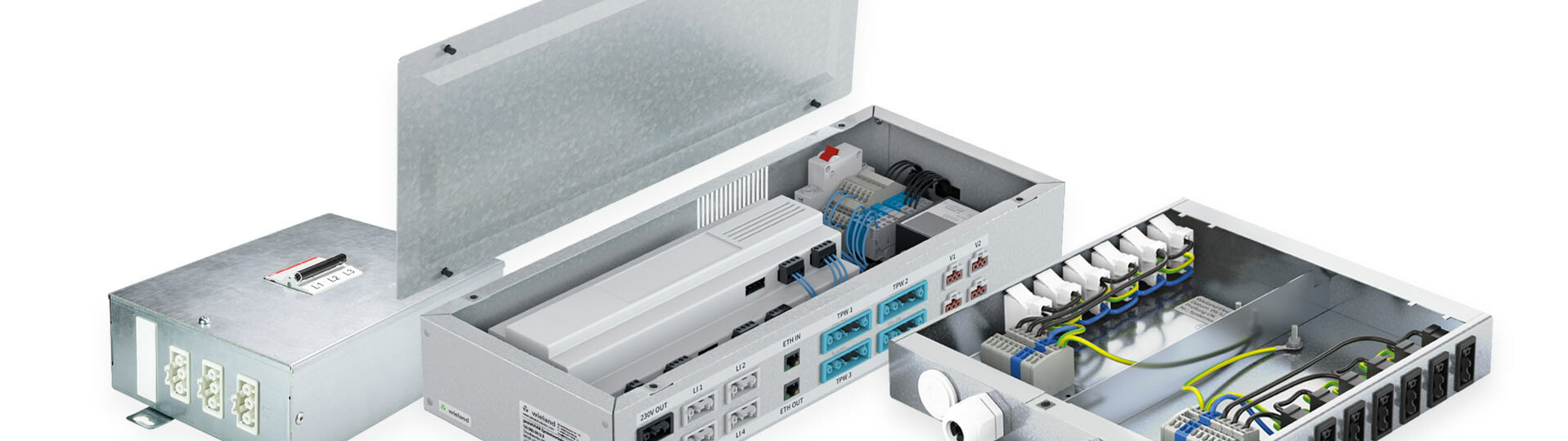

SPACE FOR ANY ELECTRONICS

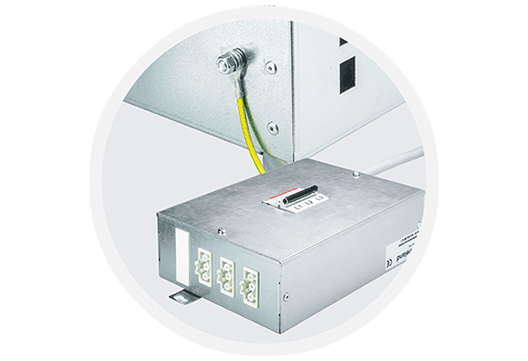

We mount any electronics in the manifolds!

- Provided MSR or automation devices from third-party manufacturers

- Wieland power supplies and surge protection

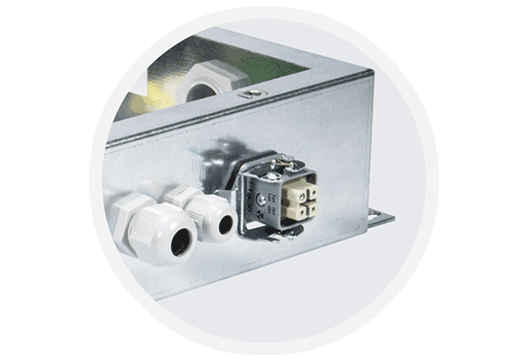

- Terminal blocks for wiring

- MCB/RCB

- Customized solutions

INSTALLATION OF THE DEVICES

All options are open here, and the design depends on the components used.

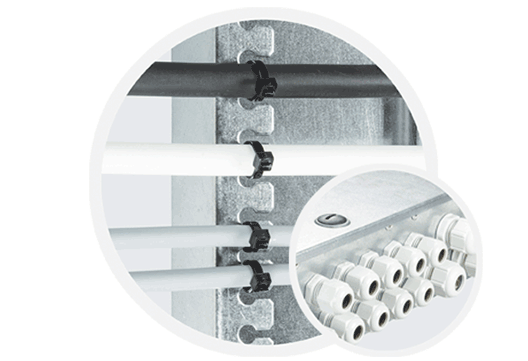

- On mounting rails of various profiles (H, G, C) flush with floor or elevated possible

- Direct mounting to the manifold bottom

- Mounting riveted or screwed to support plates

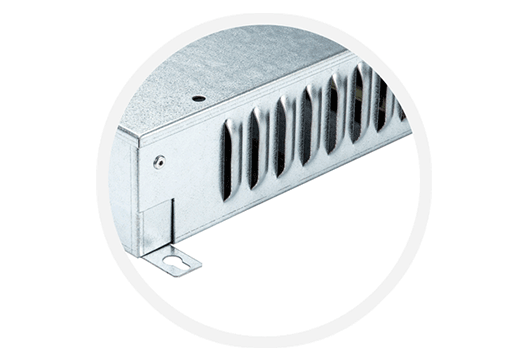

THERMAL LOAD

When installing devices with increased power loss and heat dissipation, ventilation openings may be necessary.

ACCESSIBILITY OF THE DEVICES

The internals must be accessible for commissioning, operation or troubleshooting.

- Opening the lid

- Protruding through the lid

- Standing through and covered with a flap

- Sealable

OVERVIEW DISTRIBUTION BOXES - PRODUCT FAMILY

We offer our robust distribution boxes in various designs. Of course, we are happy to advise you at any time to help you choose the right variant for your requirements:

Distribution Box MSR

This distributor accommodates all components of the MSR technology that are necessary for a floor area. In doing so, we work closely with the MSR contractors on a construction project.

Distribution Box RAU

This covers defined areas with I/Os for the automation of light, blinds and room temperature. All I/Os of a room unit are included and can be supplemented e.g. by power supplies.

DISTRIBUTION BOX RVG

Flexibility in all areas.With our empty housings we offer you the maximum possibilities for your installations. You choose the right housing for you from our standard program and supplement it with flange plates to match your required interfaces.

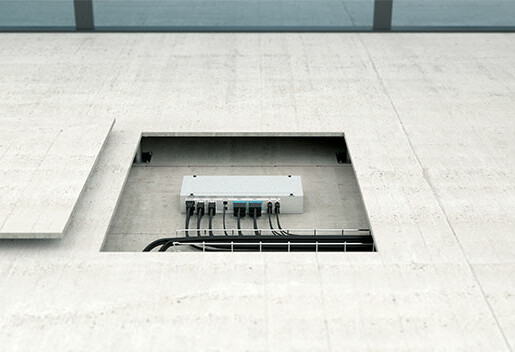

Distribution Box CPO

Consolidation Points provide the decentralized distribution point to move from fixed to pluggable installation. The consolidation points are available as pure energy or pure data distributors, but also combined. If necessary, it also records FI/LS.

Distribution Box SPZ

The distributor is particularly suitable if it can get a little damp in its environment. If the plastic housing is from a standard delivery program, all necessary components can be installed.

Distribution Box WIV

This distributor can be used, for example, to quickly electrify exhibition stands and ensure safe, reliable power distribution. Thanks to our gesis® and RST® installation connector systems, the power distributor can be installed according to the plug&play principle.

Distribution Box INS

This variant of the distribution box is used mainly in the field of school renovation/new construction. The service pole is the link between the electrical installation and your requirements for modern room automation.

Further information on the individual variants can be found on the following product pages.

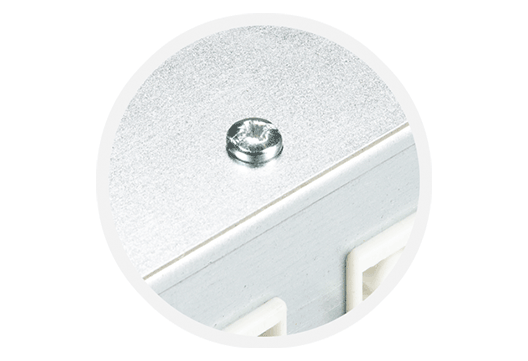

DISCOVER THE DIFFERENT COMPONENTS & MATERIALS

SMART SERVICES

From conceptual design to tendering - Our experienced employees also accompany your project on site

- Dimensioning planning

- Design and definition of electrical interfaces

- Installation planning

- Fastening design

Where necessary, we work with our customers to draft the necessary tender texts.

- For public tenders in neutral wording

- In text form (.txt or .docx)

- In GAEB

- By arrangement also in other formats

The necessary documents for the distributors are made available digitally - also in other forms at the customer's request. This saves our customers a lot of detailed work.

- Mechanical assembly diagrams

- Electrical wiring diagrams

- Parts lists

Functional components such as protective switchgear, automation devices and power supplies must be installed in the distribution board.

- Many of our customers, especially from the building automation industry, place their electronics at

- Wieland supplements the distributors with active and passive components to form functional units

To meet construction schedules, we can pick the manifolds along with other components and deliver them to the job site on time.

- For predefined units, e.g. Floors

- Distribution Boxes including external cables, connectors, etc.

- Pre-assembled, external field devices (valve actuators, dew point monitors...)

The distribution boxes are manufactured and unit-tested in accordance with the applicable standards and guidelines.

- Unit testing

- CE marking on customer request

- EMC consideration

- IP protection type consideration

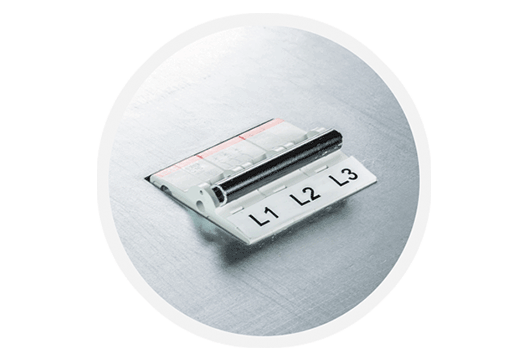

Labeling inputs/outputs and applying labels or identification numbers is essential for the creation and operation of equipment.

- Lettering individual

- Application of e.g. Built-in or preset device IDs

- Application of AKS

- Barcode or QR code creation

OUR EXPERTS

FLEXIBILITY IN THE LAYOUT

"Our smart distribution boxes allow individual rooms or entire office floors to be reallocated after the fact!"

ROBERT GERHÄUSER,

HEAD OF SALES GERMANY BUILDING INSTALLATION

WIELAND Distribution Boxes - THE BLACK BOX FOR YOUR APPLICATION

"Wieland distribution boxes support a smart building down to the installation level. They ensure easy decentralized handling of the automation systems needed to increase energy efficiency and help ensure that the electrical installation also earns the title of Smart Building Ready."

TOBIAS HENNEMANN

PRODUCT MANAGER BUILDING SOLUTIONS

FAQ

- Decentralized installation enables fast commissioning thanks to simple project planning and short installation times.

- Retrofits are flexible thanks to simple and future-proof structures.

- More net usable space, due to smaller equipment rooms. Thanks to decentralization, the automation electronics are not located in the main distribution.

- Three-phase power supply up to just before the consumer, this increases energy efficiency.

- Room automation devices are located in the respective room, fuse elements (MCB/RCB) directly on site.

A distribution board is a switchgear combination according to IEC 61439. The Wieland distribution boxes accommodate all required components of the electrical installation as well as building automation on a project-specific basis. The distributor boxes can be viewed as a black box that provides the appropriate interfaces to the field and management levels.

- Unlike conventional installation, you can lay the lines first and install the distribution box at a later time.

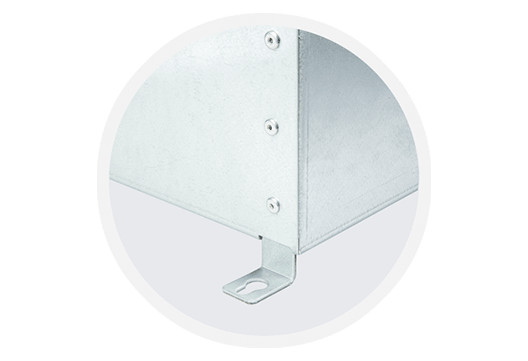

- The robust sheet steel housing protects the sensitive electronic built-in devices even in a harsh construction environment.

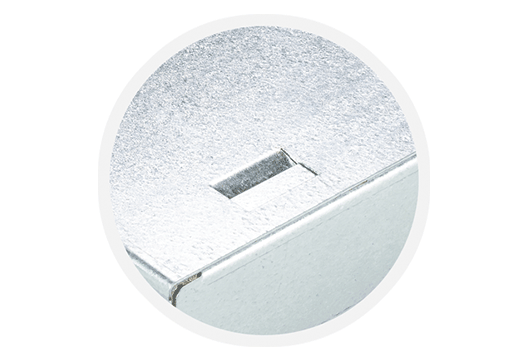

- The manifolds can be mounted on walls, ceilings and floors. For easy mounting, the attachment is made by means of keyholes placed in tabs.

- The pluggability of the installation makes it fast, easy and safe.

- Mismating is avoided thanks to the coding of the installation connector systems.

Our distribution boxes are CE certified.

Opening the system manifold does not invalidate the CE marking. However, if you make changes to the distributor, such as to the conductor cross-sections, the certification will expire.

The distribution boxes are subject to a type test, which includes EMC, temperature, IP, the IK test and the corrosion test. In addition, a routine test is carried out, which consists of a visual inspection, a short-circuit and polarity reversal test and a continuity test.

A functional test can be performed at the customer's request.

- If required, the distributors are delivered to the construction site fully parameterized and can be put into operation directly without any further on-site measures.

- The functional test is carried out by means of test plugs.

- The pluggability of our distribution boxes means that individual components can be easily replaced.

Due to our pluggable electrical installation with the gesis® installation connector system, the distribution boxes can be replaced easily and quickly. The existing infrastructure is used for this purpose.

1. IDEA

Innovative solutions are required for future-oriented building planning. A decentralized and possibly pluggable installation offers you a lot of flexibility and should be considered.

2. CONCEPTION

For presentation to builders or decision makers, we will be happy to prepare a concept for you.

Technical Contact:

Tel. +49 951 9324-996 / E-Mail: building@wieland-electric.com

Contact your local contact via our head office

Tel. +49 951 9324-0 / E-Mail: info@wieland-electric.com

3. CONCRETIZATION

You are already in the preliminary/design phase: We support you in the implementation of your concrete planning up to the cost estimate and finally to the tender.

4.TENDERING AND QUOTATION

As soon as the tender is on the market, the executing companies receive the quotations from us - and can apply for the execution .

5. ORDER

The executing company confirms the correctness of the planned execution by signing the manifold plans .The production of the manifolds is initiated.

6. DELIVERY

The piece-checked distributors, possibly with additional commissioning, are delivered to the desired address as agreed.

7. FURTHER SERVICE

If further aspects should arise, our team on site and in Bamberg is available foryouat any time .

What does a building installation with our products mean for you?

1. BASIC OVERVIEW

First of all, a few basic questions should be clarified.

- What functions are to be integrated?

- What electronics will be used?

- Which room units will be controlled?

- What construction space is available or will be needed?

- Will the plant installation be pluggable?

2. CONSULTATION APPOINTMENT

Contact us and arrange a consultation appointment with us. During this appointment necessary details can be clarified. The goals of the appointment include the specification of the distribution box, the definition of the tender text and a cost estimate.

But we will also talk about the following points:

- Determination of the electronics and internals

- Determination of the connection type

- Planning the distributor size and material

- Optimization of distribution variants and quantity structures

- Determination of accessories such as connectors or assembled cables

3. TENDER

You tender the manifolds and accessories.

- You receive a cost estimate from us

- We compile the tender texts - with pleasure also neutrally

- We handle the queries from installers

4.EXECUTION

The executing company orders the required components.

- Appointment of the Wieland project manager

- Preparation of the layout plan and EPLAN

- Final approval of the distributors by signature of the executing company

- Production and routine testing of distribution boxes in accordance with applicable standards and guidelines

- Handover of documents and plans to the contractor

What changes in the installation and the process?

1.EXCELLENCE

You create the cost calculation.

- Requesting a quotation from Wieland in accordance with the invitation to tender

- Possible need for more precise specifications

- Preparation of a net offer in case of an individual customer solution

2.FINAL DISTRIBUTION

After placing the order, order the distributor boxes.

- Appointment of the Wieland project manager

- Determination of structure and wiring - in coordination

- Striving for optimization on the basis of real conditions

- Discussion of the delivery and logistics

- Drawing preparation by Wieland Electric

- Release for production by customer

- Possibly sampling

3. MANUFACTURE AT WIELAND

The manifolds are manufactured at Wieland according to the agreements.

- Processing and, if necessary, coating of sheet metal (plastic)

- Installation and wiring of electronics and other devices, labeling of distribution boards

- Unit testing of the manifolds

4.DELIVERY

The distributor boxes will be delivered to the desired address as agreed.

- Commissioned delivery of the manifolds with further components

- Timely delivery by freight forwarder to the desired address

The software and hardware are parameterized according to customer specifications. Furthermore, labeling and commissioning takes place. Possible products from third-party systems can be integrated. In addition, we will be happy to advise you on the overall concept of decentralized electrical installation.

Yes, the tender texts are designed according to the common agreements.

YOU RECEIVE FROM US:

- Tender texts with direct reference to Wieland Electric

- Neutralized tender texts

- Tenders in the appropriate formats Word and GAEB, other formats on request

Our distribution boxes are available in a wide range of designs, so that we can cover both indoor (IP2x) and outdoor (IP6x) applications.

As standard, our distribution boxes are made of 1 mm sheet steel. For the lid, you can choose between steel plate and acrylic glass. Other materials and coatings for housings and lids are available upon request.

The housing size is customizable to meet your requirements. At the same time, we take advantage of standardization.

Yes, the Wieland distribution boxes can be colored according to your wishes.