INSTALLATION SYSTEMS OUTDOOR

RST® Connectors: Built for Safe Electrical Installations in Any Environment

Flawless Connections for Toughest Conditions:

RST® Connectors

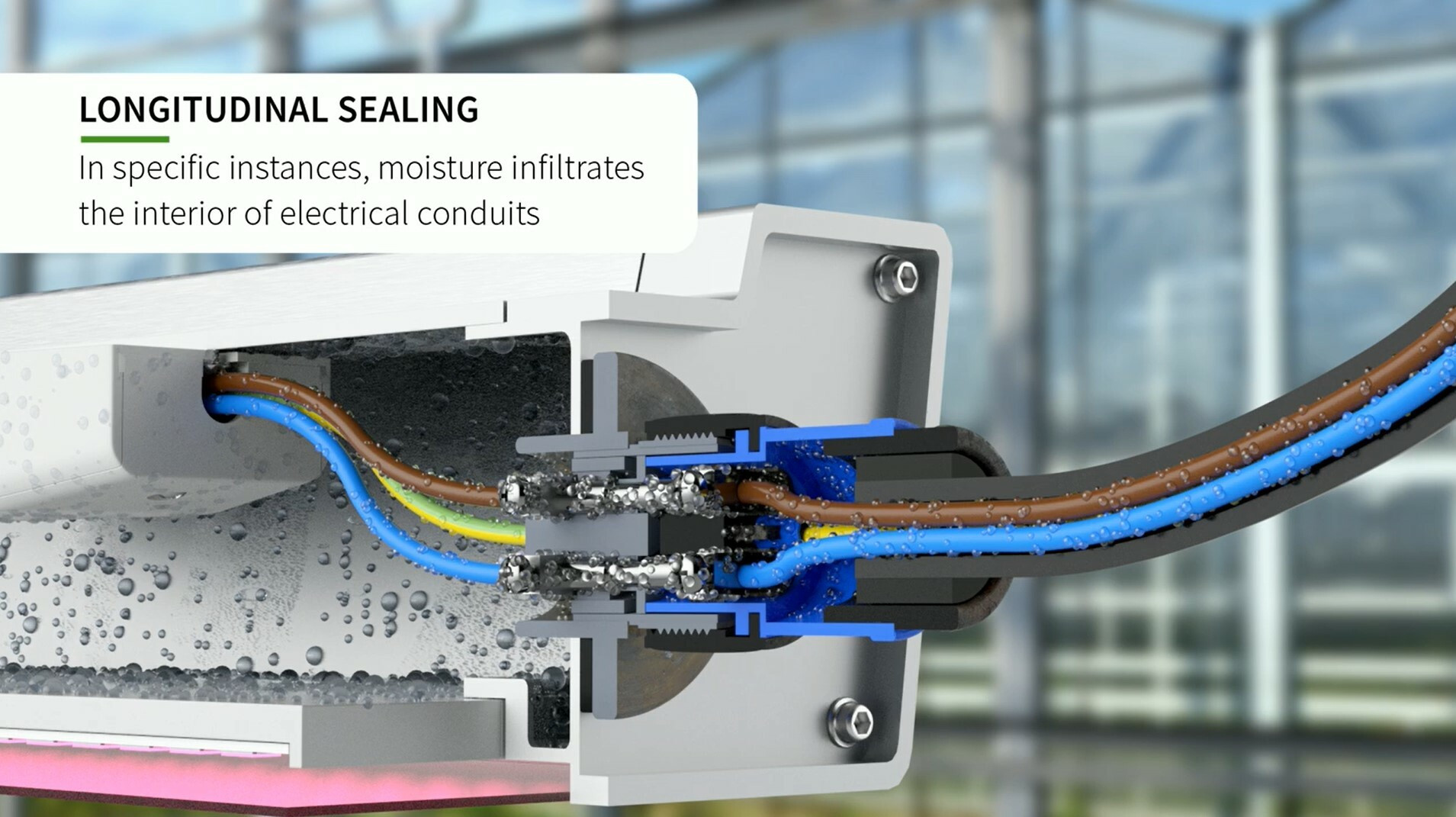

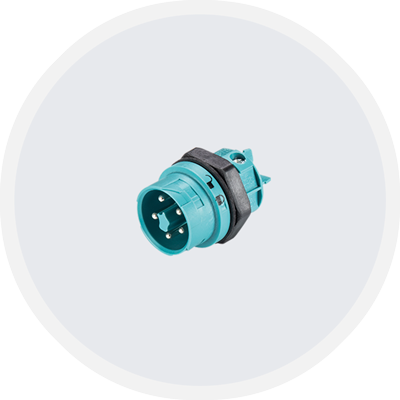

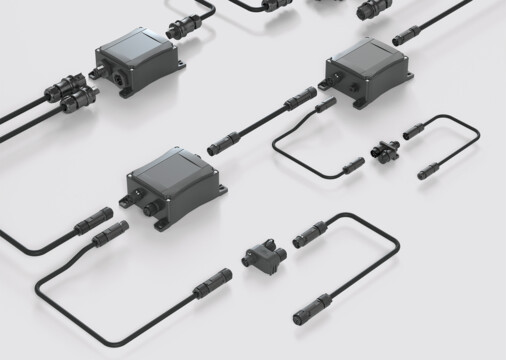

Wherever electrical connections face high demands, you need solutions that deliver flawless performance, no matter how tough the conditions are. That’s where our RST® connectors shine. Designed for high-demand environments, these connectors ensure a tight seal, exceptional mechanical strength, and unmatched reliability – even in the toughest sites.

Thanks to their compact design, RST® connectors fit seamlessly into the tightest spaces. Pre-wired and color-coded, they make installation fast, error-free, and safe, following the Plug&Play principle. With RST®, you’ll save time and guarantee safety on every project.

GET YOUR HANDS ON!

sample case RST20I3

Explore the versatility of our RST20i3 connectors with our comprehensive sample case. This kit includes a selection of 3-pole RST20 connectors in black coding, featuring both male and female connectors, device connectors, and cover pieces. Ideal for hands-on evaluation, this assortment allows you to experience the quality and functionality of our RST® CLASSIC line firsthand. Perfect for professionals seeking reliable and efficient connection solutions.