FUNCTIONAL SAFETY

FUTURE-PROOF + SCALABLE SAFETY SOLUTIONS

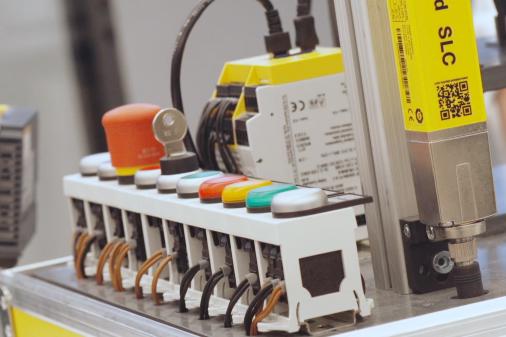

As industrial processes become more automated, the functional safety of machines and systems has to meet increasingly tougher requirements and complex configurations. Increase your performance with a scalable solution that works on individual machines and easily scales up to meet the requirements of complex manufacturing environments. Our safety portfolio includes electro-sensitive and mechanical sensors, compact relays, and powerful safety controllers with diverse safety functions.

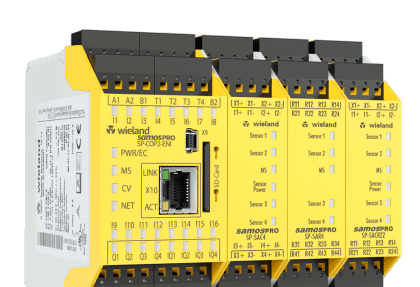

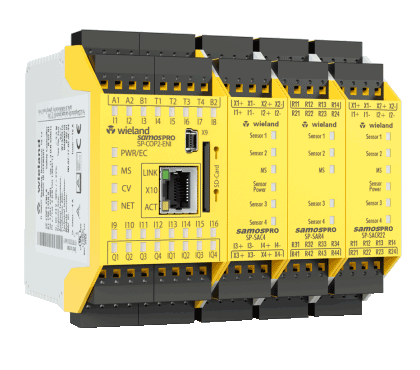

Our functional safety solutions are designed to reliably support industrial clients in motion monitoring, analog signal processing, industrial press control, and material flow. At the heart of each solution is the samos® PRO COMPACT safety logic controller. The most compact and versatile in its class, this safety controller includes a large library of TÜV-certified safety functions, integrated status and diagnosis functions, and easy-to-use programming software.

With the Wieland system, you get the following three services for machine safety in one package:

Reliably differentiating between man and material flow

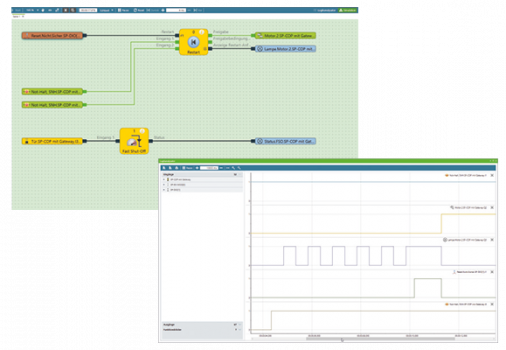

Whether in logistics, presses or packaging machines – wherever material is introduced into and removed from machines – area and access protection takes the highest priority. We offer a host of potentials for optimally realizing muting and blanking functions according to your requirements. Our portfolio comprises compact solutions that integrate intelligent sensor technology into the light curtain itself, greatly reducing the cabling complexity. The samos® PRO COMPACT safety controller allows you to realize muting functionalities in an all-encompassing way. Configuration can be done easily and intuitively using the samos® PLAN 6 programming software.

Reliable control of presses

Time-consuming programming of safety controllers are a thing of the past. The same goes for presses. The Wieland samos® PRO COMPACT safety controller is designed to simplify press configuration. All of the relevant function modules are included in our extensive TUV-certified function block library. Simply drag and drop functions, then specify your parameters. Integrated status and diagnosis information makes it easy to identify and remedy errors.

Reliable processing of analog signals

The new generation of analog input modules expand the samos® PRO safety controller module series to meet the extreme environmental and performance demands of the thermal-processing industry. Accompanying certified safety function blocks specific to the combustion industry are provided in version 1.3.0 of the samos® PLAN 6 programming software. General limit value calculations, ratios, differences and range monitoring functions can easily be created and validate.

Multiple applications for the evaluation, monitoring and visualization of analog sensors for:

- fill level monitoring

- minimum/maximum pressure

- flow rates and quantities of all types of media

- temperature monitors

- external universal transmitters

You can now use samos® PRO COMPACT to achieve all this for your project without added license costs and with up to three parallel field buses.

Which application do you need?

Contact us for a no-obligation consultation and find out how you can safeguard your machine in accordance with the international directives and standards.

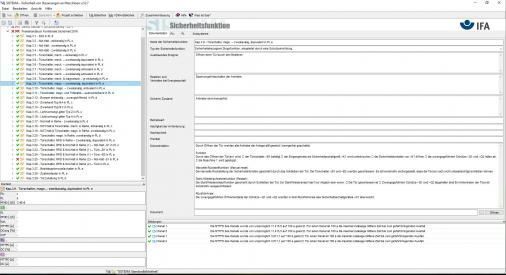

Simple calculation of performance levels

Hazard and risk analyses can be conducted using the SISTEMA software tool developed by the Institute for Occupational Safety and Health of the German Social Accident Insurance (IFA). This also allows the requisite safety functions of machines to be defined and calculated. The relevant data clusters are provided in a library for all of our customers. At the same time, all data from Wieland safety components and safety systems are uploaded to help you calculate and document the Performance Levels (PLr) in accordance with DIN EN 13849-1.

All-in-One control

Combine all functions in one safety controller to save space and cut costs. This power pack covers both your requirements, and those of your customers too. Adapt quickly and flexibly to modifications and choose the samos®PRO Compact.

Learn more about the product yourself here or contact us for a consultation.

SAMOS® PLAN 6 – intelligent safety software

Take the guesswork out of machine safety with Wieland’s intuitive software companion ─ samos® PLAN 6. Complete with a pre-loaded library of TUV certified safety function blocks, system validation & verification, and documentation, this powerful software can be tailored to manage a variety of safety standards for your machines.

If you are curious about the benefits of the samos® PLAN 6 software, try a demo today to see just how easy it is to set, validate, and verify your safety functions.

Unlike most demos, we won’t restrict the available functions for or set a time limit on our software, because we want to make machine safety easy and accessible. You can enjoy the full version for as long as you like, and simply call us when you need assistance.