SAFETY SERVICE

LEAVE THE CE-PROCESS TO US

Wieland Electric provides support for the entire service life of a machine with a comprehensive range of services, also on-site. We take you through the CE process and its various phases, or handle this completely on your behalf. We also advise you on machine safety issues and create safety-related assessments of your machines.

Achieving CE-conformity

We accompany you through the various (sub-) phases or through the entire CE process to attain the CE-mark.

- Creating the risk assessment for a machine in accordance with the Machinery Directive.

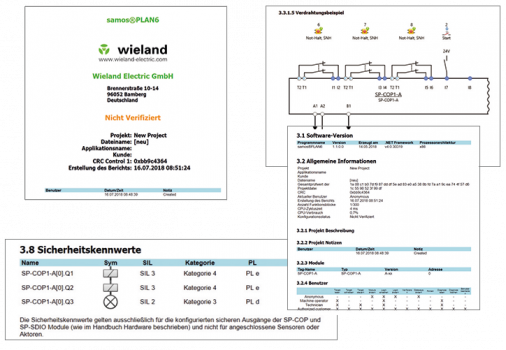

- Arithmetic proof of the performance level for each and every safety function, including documentation.

- Document validation by analyzing the customer's documents in accordance with EN ISO 13849-2 and validating the machine through tests, including documentation.

- Checking the existing operating instructions for compliance with the Machinery Directive with documentation of the test points.

- Final report with a recommendation/conclusion for the issuing the EC Declaration of Conformity by the machine manufacturer

RISK ASSESSMENT

We help you comply with the latest directives and standards to produce confirmed documentation.

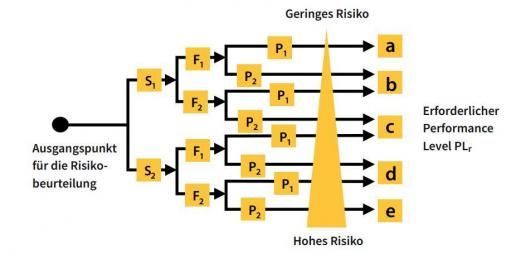

- Research into standards and directive provisions » Conducting the risk assessment in accordance with EN ISO 12100

- Documenting all hazard points

- Classifying the performance level of the hazard points

- Describing the risk minimization concepts

- Formalizing the risk minimization measures

- Final report

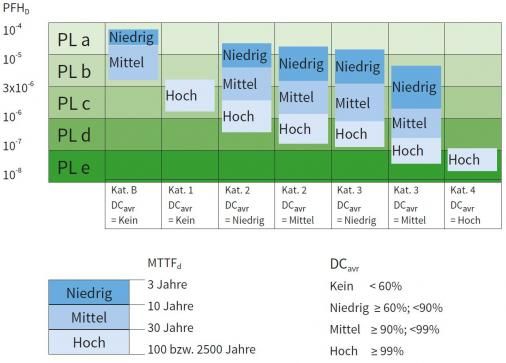

Verification to EN ISO 13849-1

Where technical safety devices in accordance with EN ISO 13849-1 are used, each individual safety function of the performance level concerned must conform to the specified performance level.

- Arithmetic proof of the performance level PL for each and every safety function.

- Documenting the verification using the IFA SISTEMA tool.

Validation to EN ISO 13849-2

Where technical safety devices in accordance with EN ISO 13849-1 are used, it is necessary to confirm that the safety functions comply with the specified safety requirement of the machine. This effectively supports error avoidance during implementation/realization. We ensure that the functional safety is guaranteed.

DOCUMENT VALIDATION

- Creating the validation plan

- Analyzing the safety functions

- Documentation the validation in a confirmed customer report

MACHINE VALIDATION

- Performing the required inspections, tests and measurements

- Safety-related test (Black box test specification)

- Documentation of the tests in a confirmed customer report

Each machine must be accompanied by operating instructions (in the official language(s) of the community of the member state concerned). We will check your operating instructions for compliance with the Machinery Directive.

- Checking the existing operating instructions for compliance with the requirements of the Machinery Directive

- Documenting the test points

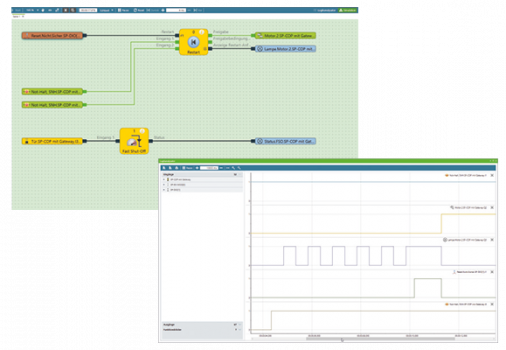

samos® PLAN 6 assists with program creation

The samos® PRO COMPACT programming tool for safety control simplifies the programming, diagnosis and documentation of all safety functions on a machine. We assist you with on-site program creation and the commissioning procedure. Our service scope also includes competent instruction and training by software experts.