- JANUARY 2025

- PRESS INFORMATION

Wieland PREFAB®: Smart solution for modular building concepts - innovation that inspires

Modular and serial construction has been revolutionizing the construction industry for some time now and is setting new standards in efficiency, cost control and sustainability. Especially in Germany, where the demand for fast and high-quality construction projects is constantly growing, this construction method is becoming increasingly important and popular. By prefabricating modules in controlled production environments, projects can not only be completed more quickly, but can also be implemented more cost-effectively, sustainably and in a way that conserves resources. A significant proportion of new residential and commercial buildings in Germany are already being built using modular construction methods - a trend that is continuing to grow. Innovative technologies such as Wieland PREFAB® are expanding the possibilities of modular construction even further. The direct integration of electrical infrastructure into precast concrete elements enables solutions that can make the construction process even more efficient and flexible.

Thanks to weather-independent production, minimal construction times and precise just-in-time delivery, precast concrete elements not only offer structural advantages, but now also a revolutionary further development in the field of electrical installation. Wieland Electric is setting a new standard here: the pluggable electrical installation is already integrated during the casting of the concrete elements - a world first that not only shortens assembly times, but also further optimizes efficiency and planning in modular construction.

World first: electrical installation permanently cast in concrete construction

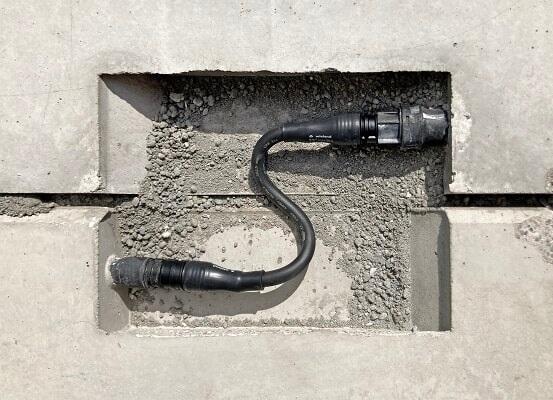

Integrating electrical installations into precast concrete elements at the factory used to involve a great deal of effort: Empty conduits had to be laid, subsequent cable ducts created and junction boxes conventionally wired and closed again. With the innovative RST® circular connector system from Wieland Electric's PREFAB solution portfolio, this process is now much simpler and more efficient. The moisture-proof system with protection class IP69 meets all technical standards and offers tested suitability for use in concrete casting - ideal for demanding architectural applications. The result: a higher degree of prefabrication of the concrete elements and a significant reduction in processing on the construction site. The prefabricated, pluggable electrical installation - consisting of supply lines, connecting and distribution pieces - is cast directly into the concrete during the production process. On the construction site, the elements only need to be connected later using plug & play. Robustness, reliability and the high protection class of the components guarantee safe and durable integration into the concrete construction. Wieland Electric has impressively demonstrated the suitability of the solution in long-term tests, opening up new possibilities for architects and construction planners for flexible and efficient construction projects.

Pluggable buildings from the distributor to the socket outlet

Wieland PREFAB® not only shows its strengths in concrete construction, but also impresses in dry construction for prefabricated buildings or components. The integration of the infrastructure cabling is designed so efficiently that the manpower required on the construction site is reduced and the electrical trade is considerably relieved. Similar to building modules, which are delivered ready for installation as standard, the gesis® installation system from Wieland Electric also relies consistently on factory pre-assembly. Suitable system and automation components as well as equipped sub-distribution boards are supplied already prepared and can be simply plugged in both in the factory and on site. Time-consuming work such as shortening, stripping, stripping and wiring is therefore a thing of the past. The coded plug connections also ensure maximum functional reliability. A particular advantage: In contrast to conventional plug-in connection systems, the gesis® and RST® systems can also be installed in areas that are no longer accessible later. This makes PREFAB system components ideal for all construction methods in modular construction and enables precise and time-saving implementation. Not only architects and planners benefit from this flexibility and the significantly simplified coordination of construction processes.

Wieland Electric at BAU 2025

January 13 to 17, 2025

Munich Trade Fair

Hall A2 Stand 439

Photo 1 (plug connection) – Simple, fast, safe: plug & play!

Photo 2 (across modules and trades) – Cross-module and cross-trade plugged and connected.