RETROFIT FOR THE SAFE CONTINUED OPERATION OF WIND TURBINES

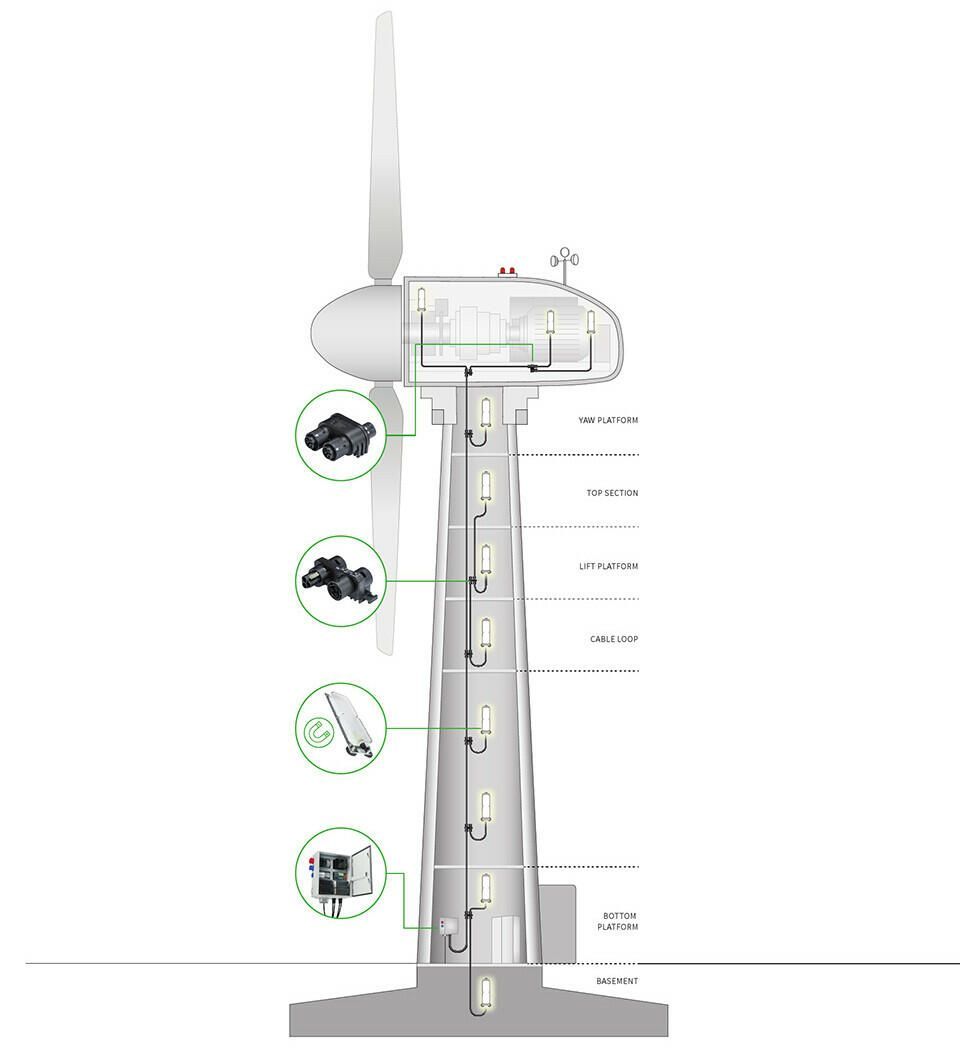

WIELAND ELECTRIC SUPPORTS WIND TURBINE OPERATORS WITH COMPLETE SYSTEM FOR EASY RETROFITTING OF WORK AND SAFETY LIGHTING

Many wind turbines (WTG) will lose their entitlement to remuneration under the Renewable Energy Sources Act (EEG) this year. This initially applies to turbines with a total output of just under 4,000 megawatts. Until 2025, additional wind turbines with an average of up to 2,400 megawatts will follow annually. However, even after their remuneration period has expired, the benefits of these turbines are considerable, partly due to their contribution to climate protection and the conservation of resources through the use of existing infrastructure. In good wind locations, wind turbines can continue to operate for years even after they have reached their design life of 20 years and are depreciated.

The condition of all components relevant to stability and the functionality of the safety equipment, turbine control and braking systems are decisive for such continued operation. The framework conditions for this are defined in the principles for carrying out an assessment and inspection of the continued operation of onshore wind turbines (BPW). The working and safety lighting of the wind turbine is also part of the tests. Here, Wieland Electric supports plant operators with a complete system that can be retrofitted quickly and easily without having to dismantle the existing lighting.

It is a centrally supplied safety lighting system based on a secondary voltage of 48VDC (SELF) or normal mains voltage of 230V AC, providing at least 30 minutes of buffering after a mains failure. Longer times can be achieved with stronger batteries. In contrast to outdated technology where the batteries were installed in the luminaires, Wieland Electric offers a central battery solution as well as modern, safe LED technology that can be easily maintained. Optionally, a light simulation including documentation of the lighting values at the workplaces and escape routes can also be carried out.