ERROR PREVENTION THROUGH PLUGGABLE ELECTRICAL INSTALLATION

HERE'S HOW TO AVOID FIVE COMMON ELECTRICAL INSTALLATION MISTAKES

Malfunctions, material damage or even life-threatening accidents can be the result if something goes wrong with the electrical installation. Dominik Stöcklein, Product Manager Indoor Systems / gesis® at Wieland Electric, knows which errors occur frequently and how they can be avoided.

1. VIOLATION OF THE CORE INSULATION

Incorrect or misadjusted tools can cause damage to the insulation when stripping cables. This mishap can cause more than just a malfunction. This does not happen with pre-assembled cables such as those offered by Wieland Electric. On the one hand, the cables are manufactured industrially, which guarantees clean stripping. On the other hand, the connectors encase the cores with appropriate clearance and creepage distances to the contactable surface, which ensures maximum safety.

2. CLAMPING THE INSULATION

Depending on the type of cable, it is quite possible that too little insulation is stripped. If, in addition, the clamping point for the cross-section is very generous, the insulation is quickly under-clamped at the point of the conductor. The insidious thing about it is that it may not be noticed immediately. Even if a malfunction is triggered, the error must be searched for laboriously. In the worse case, the clamping point has light contact and the functional test is positive. However, overheating can occur during subsequent loading, which, in addition to a malfunction, can even cause a fire. Pre-assembled cables are usually manufactured automatically and piece tested. If they are handmade, this is always done in an optimal environment and also ends with a routine check. This makes it virtually impossible for the insulation to become trapped.

3. PARTLY EXPOSED CORES

If the connection depth is smaller than expected, it often happens that the insulation is stripped too long and the bare wire protrudes. In this case, there is literally tension in the air, which can be life-threatening if touched. In addition, it is possible that the acceptance of the equipment will be denied. The consequences are costly troubleshooting and rework. Another problem is that each manufacturer can refer to its technical specifications in the event of damage and the installer must bear the consequences. This does not happen with ready-made cables, as they are manufactured in an optimal and monitored environment and can be installed precisely and safely.

4. SPLICED STRANDS AT THE CLAMPING POINT

Anyone who has ever had a spliced individual strand stuck in their finger when connecting a fine-stranded cable knows that this is painful, but still the least of the evils. Once the system is energized and the stranded wire also touches another conductor, the short circuit is perfect. In the best case, a protective device trips or a malfunction occurs. In the simplest case, both require time-consuming troubleshooting. However, if the stranded wire goes unnoticed, it can even lead to a voltage accident with life-threatening consequences at the next opportunity - a mistake that can be avoided with pre-assembled and piece-tested cables.

5. FAULTY INSULATION COORDINATION

In electrical installations 230 / 400 V and extra-low voltages in SELV and FELV versions are required. Both the selection of the cables and the safe separation of the systems are very important. A mistake here can lead to serious voltage accidents. The pluggable electrical installation is individually tailored to the respective application and cannot be confused with each other due to clean separation - for example for DALI, SMI, mains application and KNX.Even if, for example, DALI and SMI should use the same connectors, in the worst case this can only lead to a malfunction, but not to a dangerous situation.

Dominik Stöcklein, Product Manager Indoor Systems / gesis® at Wieland Electric, knows which mistakes often occur during electrical installation and how they can be avoided. (Image: Wieland Electric)

In addition to choosing the right tool, the use of user-friendly components and systems also plays an important role in safe and error-free electrical installation. (Image: Fontanis - stock.adobe.com)

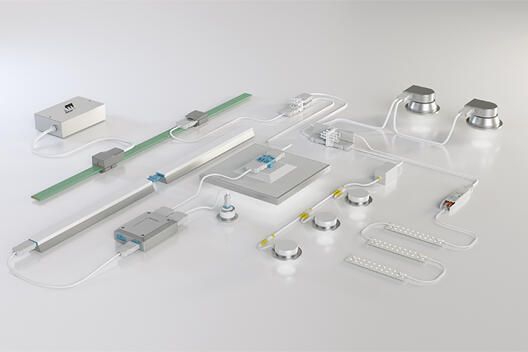

With pluggable, industrially prefabricated components and systems, common mistakes in electrical installation can be avoided and, in addition, 70 percent time can be saved through fast and structured installation. (Image: Wieland Electric)