MODULAR BUILDINGS

BUILT WITH WIELAND PREFAB®

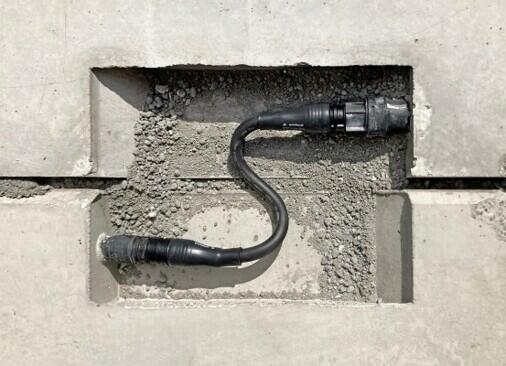

The pluggable system for electrical installation in inaccessible areas

THE FUTURE OF BUILDING!

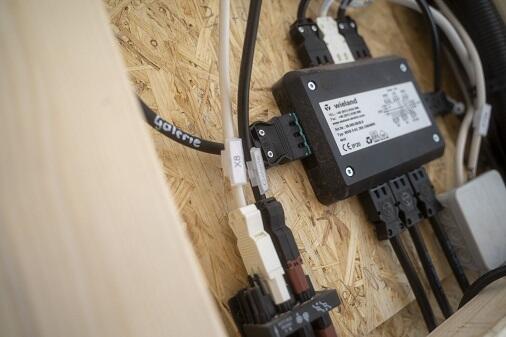

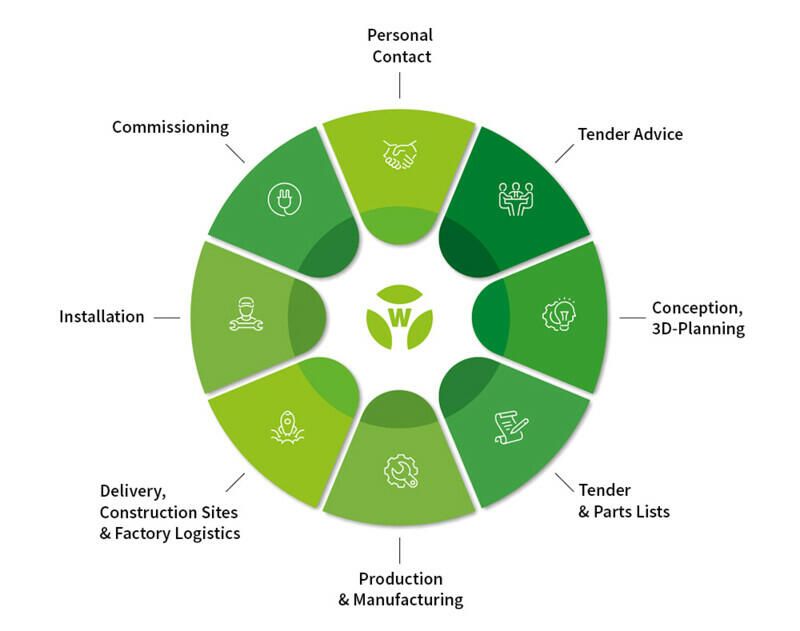

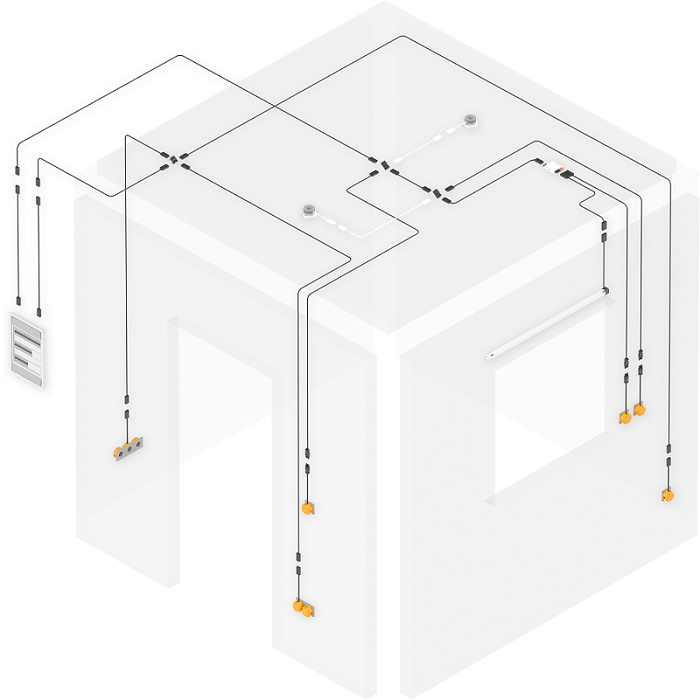

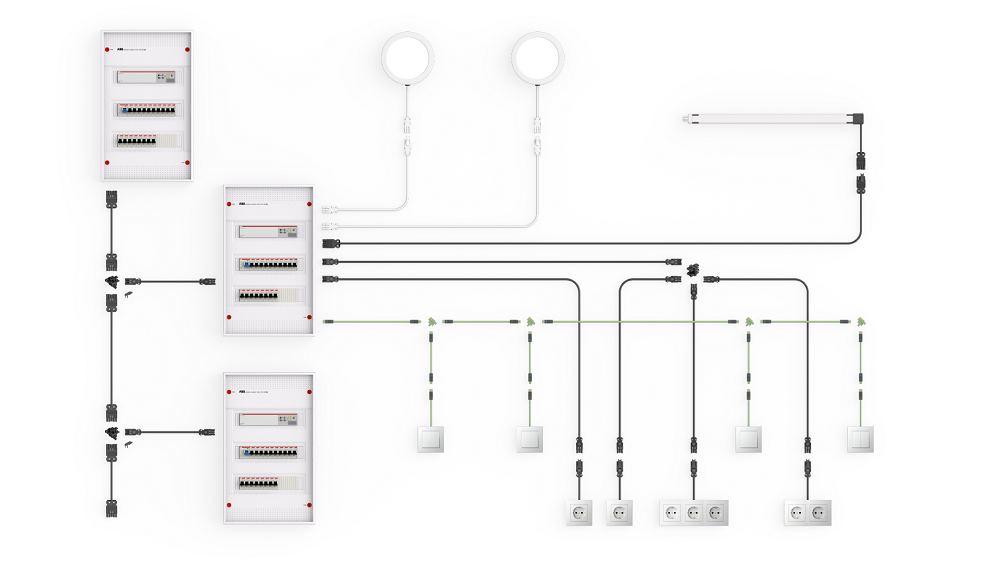

Construction is booming, and Wieland Electric is continuing to drive the momentum: Wieland PREFAB® makes modular construction even more efficient. Our pluggable electrical installation systems can already be integrated into the process of industrial prefabrication, avoiding the need for intricate and time-consuming activities in the factory and on the construction site.

In addition to our well-designed solutions ranging from sub-distribution and infrastructure cabling to pre-assembled devices (e.g., sockets, switches), we support planners, civil engineers, and electrical contractors with comprehensive services and planning tools – for streamlined, speedy, and safe construction processes.

DIGITAL SUPPORT

FROM PLANNING TO PRODUCTION

FROM THE CONCEPT

TO PRODUCTION PLANNING

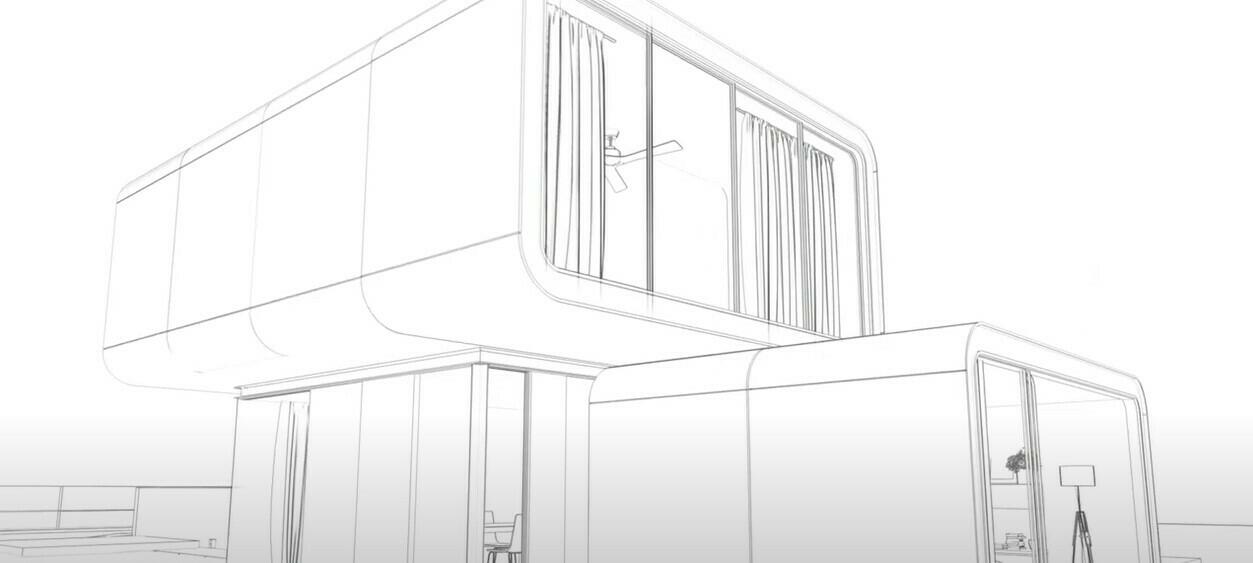

Right from the beginning of the partnership, i.e. from the first customer-specific cabling diagram to a 3D plan of the pluggable Wieland PREFAB® system, the joint process is supported digitally.

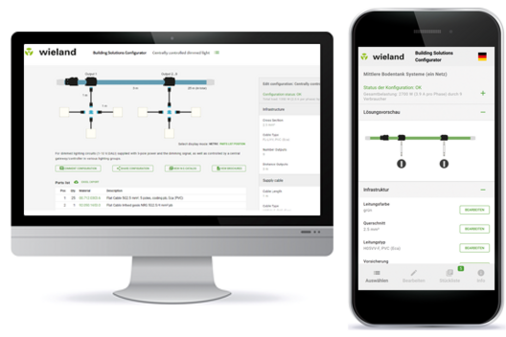

With the BSC (Building Solutions Configurator), it is possible to obtain an initial overview of the Wieland PREFAB® schematic with just a few clicks – adapted to the customer’s construction method and process. Starting from this basic concept, the Wieland PREFAB® tools can be augmented with planning data step by step all the way through to concrete plans, which are executed with the 3D planning tool BSD (Building Solutions Designer).

INNOVATIVE PLANNING TOOLS

FOR ELECTRICAL INSTALLATION

The BSD also offers the possibility of 3D data exchange with common BIM planning software, making it possible for the first time to integrate pluggable electrical installation cabling into a holistic building design. For our customers, this creates the basis for production planning, including the electrical installation, in the factory.

The generation of customer-specific parts lists, a cost calculation, and features such as current load calculations are further useful functions of the digital Wieland PREFAB® tool support.

WITH US YOU CAN RELY ON

QUALITY AND AN UNBEATABLE PARTNERSHIP

OUR EXPERTS: THE KEY TO YOUR SUCCESS

WOLFGANG LOHR

Consultation + Support

for Your Wieland PREFAB® Concepts

PETER KAUF

Head of Strategic Corporate Project Infrastructure/Wieland PREFAB®

SVEN GÜNTHER

Contact

for International Projects

THOMAS NIEBORG

Expert in Digital Wieland PREFAB®

Tools + System Integration

ANDREAS FENN

Expert in Suitability Testing +

Application of Our Connectors

CHRISTIAN MERKEL

Consultation + Support

for Your Wieland PREFAB® Concepts

TALK TO WIELAND

COME AND SEE US!

As a professional, you know exactly where you need support. As professionals, we know exactly what this should look like. The best way is for us to chat in person about how, where, and when we can support you. Please let us know your preferred contact times, and our experts will contact you promptly.

THE WIELAND PREFAB® NEWSLETTER

DIRECTLY TO YOUR MAILBOX

Do you have a need for efficient and sustainable installation solutions, both now and in the future?

Keep up to date with new developments relating to Wieland PREFAB® and subscribe to the newsletter now.

DOWNLOADS

WIELAND PREFAB® Brochure

Our 28-page brochure contains everything you need to know about our innovative electrical installation solutions for modular construction. Compact, concise, and packed with practical examples – download it now for free and learn more!